Overview

There are two basic components to how you will command the drive and how it will behave. The Command Source indicates how the drive will be communicated to. The drive has communication options via Ethernet,

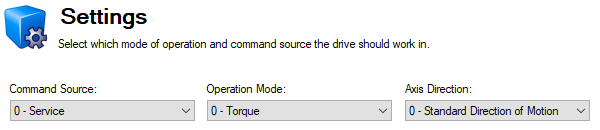

Using Command Source and Operation Modes

There are two methods to access these two parameters within WorkBench. The first is by selecting the Settings screen from the left hand tree. This displays the graphical representation of both the Command source and Operation Mode. The drop-down box then allows you to select the desired command type and control loop you wish to activate. Please note that some Command Sources can only be used with certain control loops (as an example, Electronic Gearing can only be used in Position mode).

Command Source

The command source sets how you communicate with the drive. Initially, you might be communicating via your PC using the Ethernet connection. Each Command Source is listed below:

Service

This is the most common source used when establishing initial communications with the drive to set the system up, and when you may need to “service” the drive. The Service source communicates with your PC via the Ethernet port located on the top of the drive at connector X11.

Fieldbus

When using a fieldbus, such as CANopen or EtherCAT, the drive is set to this command source.

Electronic Gearing

If the drive will be used to follow the output of an external encoder, following motion using an electronic gear ratio, then you should use this command source. When using Electronic Gearing, the Operation mode must be set in the Position Loop mode. This is also the mode used for step and direction inputs as well.

Analog

This command source allows the drive to be controlled from an analog source.

Operation Mode

The operation mode identifies which servo loop you will be controlling. The drive offers torque, velocity, or position control. From the setting screen page, a graphical representation of the loop is displayed. By clicking these graphical representations, you can access additional loop information such as gains, filters, and other settings.

Torque

In this mode, the axis runs at constant torque using the latest command value received from the controller. Once the axis is setup for Torque Mode, torque commands set a torque setpoint in the axis. Torque commands and values are scaled in milliarms.

Velocity

In this mode, the Axis is controlled via a speed setpoint sent from the controller to the drive using I/O Assembly Messaging (the Jog command). When changing velocity, the commanded acceleration and deceleration rates will be used.

Position

In this mode, the Axis runs an internal trajectory generator for moving between commanded positions. These positions can be sent directly from the controller (point-to-point moves), or pre-programmed in Motion Task sequences.

Axis Direction

The axis direction can only be set while the axis is disabled. Axis direction determines whether the axis moves in the standard or reversed direction when enabled.

Related Parameters