![]()

Function

Function![]() A function calculates a result according to the current value of its inputs.

A function has no internal data and is not linked to declared instances. - Initializes a PLCopen

A function calculates a result according to the current value of its inputs.

A function has no internal data and is not linked to declared instances. - Initializes a PLCopen![]() A vendor -and product- independent worldwide association active in Industrial Control and aiming at standardizing PLC file formats based on XML. digitizing Axis' position

A vendor -and product- independent worldwide association active in Industrial Control and aiming at standardizing PLC file formats based on XML. digitizing Axis' position![]() Position means a point in space which is described by different coordinates.

Depending on the used system and transformation it can consist of a maximum of six dimensions (coordinates).This means three Cartesian coordinates in space and coordinates for the orientation.

In ACS there can be even more than six coordinates.

If the same position is described in different coordinate systems the values of the coordinates are different. data.

Position means a point in space which is described by different coordinates.

Depending on the used system and transformation it can consist of a maximum of six dimensions (coordinates).This means three Cartesian coordinates in space and coordinates for the orientation.

In ACS there can be even more than six coordinates.

If the same position is described in different coordinate systems the values of the coordinates are different. data.

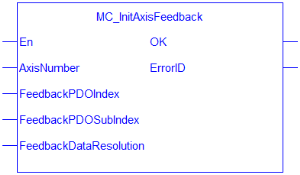

Inputs

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

OK |

BOOL |

No range |

N/A |

Indicates the initialization is complete. This output is only applicable to FFLD programs. |

|

ErrorID |

DINT |

No range |

N/A |

Indicates if the call failed or succeeded. If the call succeeds, this is set to 0 (zero). |

Remarks

- A call to this function is automatically generated when the application is compiled.

- This call is based on the data entered in the PLCopen Axis Data dialog.

Figure 1: MC_InitAxisFeedback

FBD Language Example

FFLD Language Example

Not available.

IL Language Example

Not available.

ST Language Example

(* MC_InitAxisFeedback STStructured text - A high-level language that is block structured and syntactically resembles Pascal. example *)

// Initialize the digitizing Axis (Axis #3) with the Feedback object 0x60E4 subIndex 2.

Encoder resolution is 25bits.

ErrID := MC_InitAxisFeedback(3, 16#60E4, 16#02, 25);