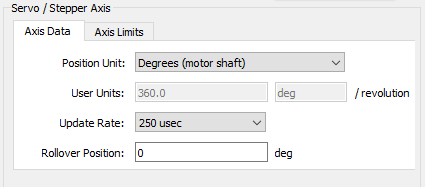

Axis Data Parameters

If a Servo/Stepper axis is selected, two tabs are available: Axis Data and Axis Limits. If a Digitizing axis is selected, only the Axis Data tab is available. By default, new axes will be defined using degrees as the measurement unit.

Figure 4-22: Servo/Stepper Axis - Axis Data

The Servo/Stepper Axis - Axis Data parameters are:

| Parameter | Description |

|---|---|

| Position Unit |

This field sets the units (see UNIT Parameters ) used by the drive axis. When the axis is defined as an AKD2G the controller applies the user units value and label to the drive. These user units will be applied for both Op-mode (running application) and Pre-Op mode (online config) when the EtherCAT

|

| User Units / Revolution |

The value used to define an axis position or distance for an axis. The default values are: Counts: 65,536 / revolution Radian: 6.28318530717 (or 2π) / revolution Degree: 360 / revolution When the Unit is set to Custom you may enter your own value and units name, such as |

| Update Rate |

The rate at which the axis's feedback is read and a new command position is generated. The choices are:

This rate can be slower or equal to the EtherCAT Cycle Time If you select an axis Update Rate which is faster than the EtherCAT Cycle Time, the axis is set to run at the EtherCAT Cycle Time. |

| Rollover Position |

The value at which the axis position rollovers to zero. Rollover Position is specified in User Units. For example: If the rollover position is 1000, the axis position counts up from 0 to 999 and then rollover back to 0. In the reverse direction, the axis position counts down to 0 and then rollover to 999. If Rollover Position is 0, no rollover occurs. Axis positions become negative values when counting down below 0. |