How To Set Up a Variable to Monitor Safety Data

This example walks you through setting up a variable which can be used to monitor data from a safety device. The project for this example has a BBH SCU and an AKD2G.

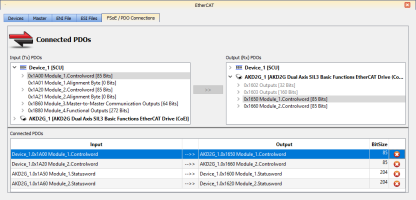

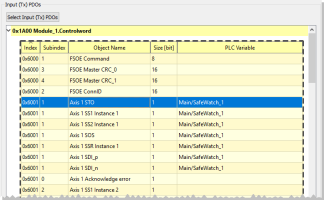

- Connect the SCU and drive PDOs. (See FSoE / PDO Connections Tab)

While this step is optional, it is quite useful and will save you time and effort.

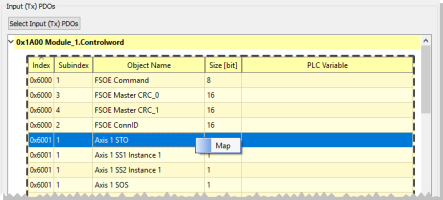

- Right-click (or double-click) on an Input (Tx) PDOs object that will be monitored and select Map.

It is recommended that you use Tx PDOs as the source for a variable as they update every cycle, where Rx PDOs may not be current.

- Read-Only variables are the only ones that will be shown in the PLC

"Programmable Logic Controller"

A Programmable Logic Controller, PLC, or Programmable Controller is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines.

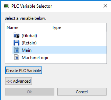

Used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events Variable Selector. Click Create PLC Variable. In this case we are creating the variable inside of Main.

"Programmable Logic Controller"

A Programmable Logic Controller, PLC, or Programmable Controller is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines.

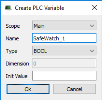

Used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events Variable Selector. Click Create PLC Variable. In this case we are creating the variable inside of Main. - Define a variable by giving it a name, type, and optionally an initial value, and click OK.

- The PLC Variable Selector now displays variable. Click OK.

The variable is now assigned and available to monitor any object in the same Index:Subindex.