Limitations for SMM 1.04

|

SMM

|

Limitation |

Remarks |

Solved in SMM FW |

|---|---|---|---|

|

1.04 |

Multiple devices per safety group |

Limited to 1 device for FS2 safety groups.

|

1.12 |

| 1.04 | Safe absolute position range: If the safe absolute position range is set to “Signed”, the total accuracy of the safe position is ±1 Digit for the selected user unit. | Workaround: Use a user unit of lower magnitude, or use “Unsigned” safe position range. | 02-00-000 |

| 1.04 | Dual brake on single axis drive cannot be configured using FSoE SRA parameters. | Workaround: Use Kollmorgen WorkBench safety parameters, which can be downloaded through fieldbus. instead of FSoE SRA parameters. | 1.12 |

| 1.04 | Depending on your FSoE Master (e. g. BBH), in combination with FW 02-10-00-103, dual brake on dual axis drive cannot be configured using FSoE SRA parameters | Workaround: Use Kollmorgen WorkBench safety parameters (which can be downloaded through fieldbus) instead of FSoE SRA parameters, or downgrade drive FW to 02-05-03-002. | N/A (only affects SMM1 with drive FW 02-10-00-103) |

| 1.04 | Depending on your FSoE Master (e. g. BBH), in combination with drive FW 02-10-00-103, SBC cannot be deselected on axis 2 using FSoE SRA parameters. | TwinSAFE FSoE Masters are not affected.

Workaround: Use Kollmorgen WorkBench safety parameters (which can be downloaded through fieldbus) instead of FSoE SRA parameter, or downgrade drive FW to 02-05-03-002. |

N/A (only affects SMM1 with drive FW 02-10-00-103) |

|

1.04 |

SS1 active signal in the FSoE status word |

The FSoE status word will return SS1 selected instead of SS1 active.

|

1.12 |

|

1.04 |

SafeID validation via FSoE does not invalidate persistent safety parameters |

It is possible to validate the SafeID though FSoE when using FSoE SRA parameters. Due to some limitations validation may not clear the existing persistent parameters.

|

|

|

1.04 |

Do not use distinct test pulses |

Due to some limitations, it is advised to not use the feature “Distinct Pulse Monitoring” and to disable it in the parameters editor (Common / Inputs).

|

1.12 |

|

1.04 |

EnDat 2.2 is not supported |

Any safety configuration containing EnDat 2.2 as a safe encoder will be rejected.

|

|

|

1.04 |

Default value of the position increment in user unit is 360 instead of 3600 with FSoE SRA parameters |

When using FSoE SRA parameters, the default value of the position increment in user unit is 360 while the position factor unit default value is “deci” and the position user unit is “Degree”.

|

1.12 |

|

1.04 |

SLI: Configuration with s_LL_SLI bigger than s_UL_SLI gets rejected |

It is not possible to set s_LL_SLI bigger than s_UL_SLI. These configurations gets rejected by the safety module.

|

1.12 |

|

1.04 |

SS2: SS2 requires SOS velocity monitoring |

The parameter n_Zero_SOS is required by SS2. It is used by the SS2 velocity monitoring to activate SOS when the axis is ready. Workaround: Set the velocity monitoring of SOS to enabled and set the value of n_Zero_SOS to match the expected behavior (usually to a value bigger than zero). |

|

|

1.04 |

With FSoE parameters, the Axis 1 “SDIn moving” safe signal cannot be mapped to a SOUT. |

Note that the SDIn Moving signal of Axis 1 can still be linked to the FSoE status word. Workaround: use WorkBench parameters.. |

1.12 |

|

1.04 |

SDB function with vertical load |

Vertical load might fall under certain conditions while enable/disable power stage by SDB function. Workaround: - |

02-00-000 |

|

1.04 |

SAR can not be configured to be activated by FSoE on Axis 2. |

Workaround: Control SAR on Axis 2 via safe inputs or use two single axis drives instead of a dual axis drive |

02-00-000 |

|

1.04 |

Position monitoring limits have to be less than half of the max. position with SOS/SLI/SDI. |

When using position monitoring with functions that use relative position (SOS/SLI/SDI), the position limit parameters (upper and lower) have to be less than half of the max. position of the encoder. Workaround: - |

|

|

1.04 |

Position monitoring limits have to be less than half of the max. position with SOS/SLI/SDI and signed-range. |

When using position monitoring with functions that use absolute position (SOS/SLI/SDI), the position limit parameters (upper and lower) have to be less than half of the max. position of the encoder when using a singed range. For an unsigned range, the position limit parameters have to be less than the max. position of the encoder. Workaround: - |

|

|

1.04 |

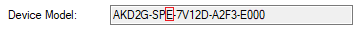

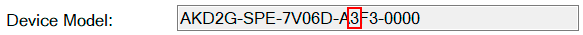

The deceleration ramp parameters for the safety functions SS1 (a_SS1), SS2 (a_SS2), SLS (a_SLS), and SSR (a_SSR) are using the defined velocity user unit per second instead of the defined acceleration user unit. |

Example:

Workaround: - |