AKT2G-SDO-004-000

Jump to a section on this page:

Safety Terminal with Four Digital Fail-safe Outputs

The AKT2G-SDO-004-000:

- Is a safe output terminal with digital outputs for connecting actuators (contactors, relays, etc.) with a maximum current 0.5A (24VDC).

- The Bus Terminal has 4 fail-safe outputs.

- Meets these requirements:

- IEC 61508:2010 SIL 3

- DIN EN ISO 13849-1:2015 (Cat 4, PL e)

- UL508, UL1998, and UL991

The safety terminal has the typical design of an EtherCAT terminal.

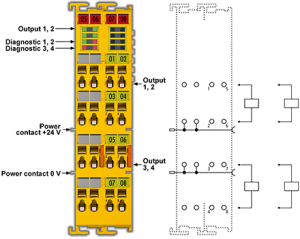

Figure 1: AKT2G-SDO-004-000 Safety Terminal with Four Digital Fail-safe Outputs

-

-

Be sure to review:

Related Topics: Map Input and Output to Variables

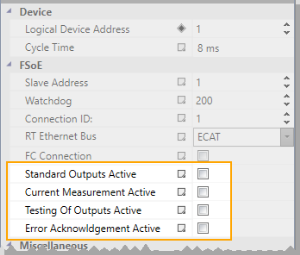

Example: Using the BBH SafePLC2 software, the parameters can be configured from the AKT2G-SDO-004-000 Properties:

Intended Use

-

-

Caution - Risk of injury!

Safety components may only be used for these purposes:

The safety terminals expand the application range of the E-Bus terminal system with functions that enable them to be used for machine safety applications.

- The safety terminals are designed for machine safety functions and directly associated industrial automation tasks.

- Therefore, they are only approved for applications with a defined fail-safe state.

- This safe state is the wattless state.

- Fail-safety according to the relevant standards is required.

The safety terminals enable connection of:

- 24VDC sensors (AKT2G-SDI-004-000) such as emergency off push-button switches, pull cord switches, position switches, two-hand switches, safety mats, light curtains, light barriers, laser scanner, etc.

- 24VDC actuators (AKT2G-SDO-004-000 such as contactors, protection door switches with tumbler, signal lamps, servo drives, etc.

-

-

Test pulses

When selecting actuators, verify the AKT2G-SDO-004-000 test pulses do not lead to actuator switching or diagnostic message from the AKT2G-SDO-004-000.

Safety components have been developed for these tasks:

- The AKT2G-SDI-004-000 is an EtherCAT Terminal with 4 digital fail-safe inputs.

- The AKT2G-SDO-004-000 is an EtherCAT Terminal with 4 digital fail-safe outputs.

These safety components are suitable for operation on the Kollmorgen AKT2G-ECT-000-000 series Bus Couplers.

-

-

Power supply from SELV/PELV power supply unit!

The safety components must be supplied with 24VDC by an SELV/PELV power supply unit with an output voltage limit Umax of 36VDC.

Failure to observe this can result in a loss of safety.

-

-

Follow the machinery directive!

The safety components may only be used in machines as defined in the machinery directive.

-

-

Ensure traceability!

The buyer has to ensure the traceability of the device via the serial number.

Technical Data

| Technical Data | |

|---|---|

|

Product Designation |

AKT2G-SDO-004-000 |

|

Number of outputs |

4 |

|

Status display |

4 (one green LED per output) |

|

Error reaction time |

≤ watchdog times |

|

Output current per channel |

With parameter current measurement active set:

|

|

Actuators |

When selecting actuators, please ensure that the AKT2G-SDO-004-000 test pulses do not lead to actuator switching. |

|

Cable length between actuator and terminal |

|

|

Wire cross section |

Minimum 0.75 mm2 |

|

Input process image |

6 bytes |

|

Output process image |

6 bytes |

|

AKT2G-SDO-004-000 supply voltage (PELV) |

24VDC (–15%/+20%) |

|

Current consumption via E-bus |

Approximately 221mA |

|

Power dissipation of the terminal |

Typically 2W |

|

Electrical isolation (between the channels) |

No |

|

Electrical isolation (between the channels and the E-bus) |

Yes |

|

Insulation voltage (between the channels and the E-bus, under common operating conditions) |

Insulation tested with 500VDC |

|

Dimensions (W x H x D) |

24mm x 100mm x 68mm |

|

Weight |

Approximately 100g |

|

Permissible ambient temperature (operation) up to SW 03 |

0°C to +55°C See the note in Installation Position and Minimum Distances. |

|

Permissible ambient temperature (operation) from SW 04 (week 02/2014) |

-25°C to +55°C See the note in Installation Position and Minimum Distances. |

|

Permissible ambient temperature (transport/storage) |

-40°C to +70°C |

|

Permissible air humidity |

5% to 95%, non-condensing |

|

Permissible air pressure (operation/storage/transport) |

750hPa to 1100hPa This corresponds to a height of approximately -690m to 2450m over sea level assuming an international standard atmosphere. |

|

Climate category according to EN 60721-3-3 |

3K3

|

|

Permissible level of contamination according to EN 60664-1 |

Level of contamination 2 Comply with the Safety I/O Maintenance section. |

|

Impermissible operating conditions |

Safety terminals must not be used under these operating conditions:

|

|

EMC immunity/emission |

Conforms to EN 61000-6-2 / EN 61000-6-4 |

|

Vibration/shock resistance |

Conforms to EN 60068-2-6 / EN 60068-2-27 |

|

Shocks |

15g with pulse duration 11ms in all three axes |

|

Protection class |

IP20 |

|

Permitted operating environment |

In the control cabinet or terminal box, with minimum protection class IP54 according to IEC 60529 |

|

Permissible installation position |

|

|

Approvals |

CE, cULus |

Safety Parameters

|

Key Figures |

AKT2G-SDO-004-000 |

|---|---|

|

Lifetime [a] |

20 |

|

Prooftest Interval [a] |

Not required 1 |

|

PFHD |

1.25E-09 |

|

%SIL3 |

1,25 % |

|

PFD |

8.45E-05 |

|

%SIL3 |

8,45 % |

|

MTTFd |

High |

|

DC |

High |

|

Performance level |

PL e |

|

Category |

4 |

|

HFT |

1 |

|

Element classification 2 |

Type B |

- Special proof tests are not required during the entire service life of the AKT2G-SDO-004-000 EtherCAT terminal.

- Classification according to IEC 61508-2:2010 (section 7.4.4.1.2 and 7.4.4.1.3)

The AKT2G-SDO-004-000 EtherCAT Terminal can be used for safety-related applications within the meaning of IEC 61508:2010 up to SIL3 and EN ISO 13849-1 up to PL e (Cat4).

For the calculation or estimation of the MTTFd value from the PFHD value, more information is in ISO 13849-1:2015 Table K.1.

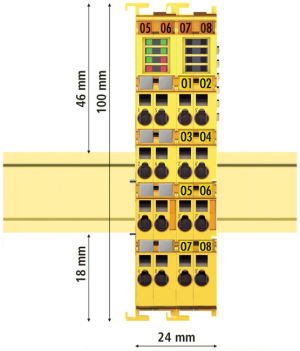

Dimensions

|

|

Figure 2: Dimensions of the AKT2G-SDO-004-000

Block Diagram

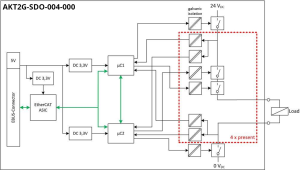

Figure 3: Block Diagram of the AKT2G-SDO-004-000

The block diagram shows the basic configuration of a channel in the AKT2G-SDO-004-000.

- The part with a red border is present four times in the terminal.

- The high-side and low-side switches only exist once for all channels.

- This means that each channel has a total of four stop paths.

Pin Assignment

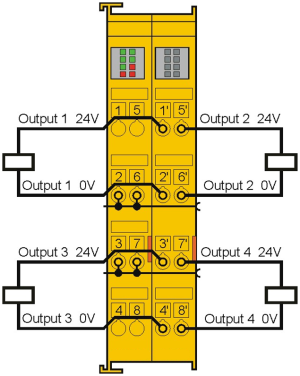

Figure 4: AKT2G-SDO-004-000 Pin Assignment

| Pin Assignment - AKT2G-SDO-004-000 | ||

|---|---|---|

| Terminal Point | Output | Signal |

|

1 |

- |

not used, no function |

|

2 |

positive power contact |

|

|

3 |

- |

negative power contact |

|

4 |

not used, no function |

|

|

5 |

- |

not used, no function |

|

6 |

positive power contact |

|

|

7 |

- |

negative power contact |

|

8 |

not used, no function |

|

|

1’ |

1 |

Output 1+ |

|

2’ |

Output 1- |

|

|

3’ |

3 |

Output 3+ |

|

4’ |

Output 3- |

|

|

5’ |

2 |

Output 2+ |

|

6’ |

Output 2- |

|

|

7’ |

4 |

Output 4+ |

|

8’ |

Output 4- |

|

-

-

Test Pulses

When selecting actuators, verify the AKT2G-SDO-004-000 test pulses do not lead to actuator switching or diagnostic message from the AKT2G-SDO-004-000.

Signal Cables

Permitted Cable Length

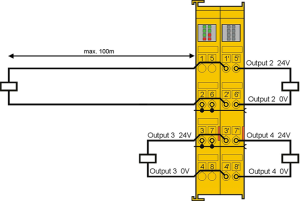

Figure 5: Permitted Cable Length

When connecting a single switching contact via its own continuous cabling (or via a non-metallic sheathed cable), the maximum permitted cable length is 100m.

The use of contact points, connectors or additional switching contacts in the cabling reduces the maximum propagation.

Cable Routing

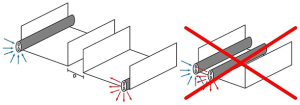

Figure 6: Cable Routing

-

-

Route the signal cable separately!

The signal cable must be routed separately from potential sources of interference (e.g., motor supply cables, 230 VAC power cables etc.)!

Interference caused by cables routed in parallel can influence the signal form of the test pulses and thus cause diagnostic messages (e.g., sensor errors or OpenLoad errors).

- D: Distance between the cable ducts should be as large as possible.

- Blue arrows: signal line.

- Red arrows: potential source of interference.

The common routing of signals, together with other clocked signals in a common cable, also reduces the maximum propagation, since crosstalk of the signals can occur over long cable lengths and cause diagnostic messages.

The test pulses can be switched off (sensor test parameter) if the connection of a common cable is unavoidable. However, this leads to a reduction in the degree of diagnostic cover when calculating the performance level.

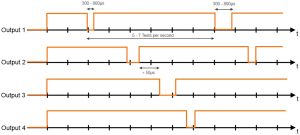

Test Pulses

The typical length of test pulse (switching from 24 V to 0 V and back to 24 V) is 300µs to 800µs.

Testing usually takes place 5 to 7 times per second.

-

-

Test pulses for the outputs

This diagram shows a typical test pulse curve for the four outputs of an AKT2G-SDO-004-000.

The parameters Current measurement active and Testing of outputs active are enabled.

Figure 7: Typical course of test pulses of the outputs.