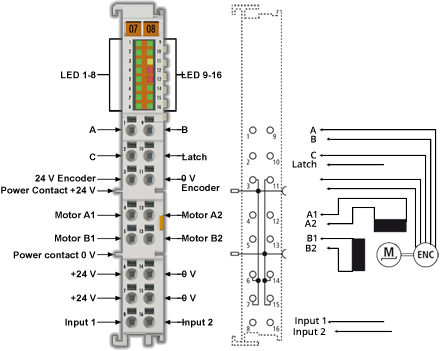

AKT2G-SM-L15 LEDs and Connections

-

-

WARNING! Risk of electric shock and damage of devices possible!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or wiring of the Bus Terminals!

Figure 1: LEDs and connection of the AKT2G-SM-L15

LEDs

| No. | LED | Color | Meaning | |

|---|---|---|---|---|

|

1 |

RUN |

green |

This LED indicates the terminal's operating state: |

|

|

off |

State of the EtherCAT State Machine: INIT = Initialization of the terminal or BOOTSTRAP = Function for firmware updates of the terminal |

|||

|

blinking |

State of the EtherCAT State Machine: PREOP = Setting for mailbox communication and variant standard settings |

|||

|

single flash |

State of the EtherCAT State Machine: SAFEOP = Channel checking of the Sync Manager and the Distributed Clocks. Outputs stay in safe operation mode. |

|||

|

on |

State of the EtherCAT State Machine: OP = Normal operation mode, mailbox- and process data communication possible |

|||

|

2 |

Encoder |

green |

on |

Encoder ready for operation |

|

3 |

A |

green |

on |

Signal at encoder input A |

|

4 |

B |

green |

on |

Signal at encoder input B |

|

5 |

C |

green |

on |

Signal at encoder input C |

|

6 |

Latch |

green |

on |

Signal at latch input |

|

7 |

Turn CW |

green |

on |

Motor is triggered clock wise |

|

8 |

Input 1 |

green |

on |

Signal at digital input 1 |

|

9 |

Driver |

green |

on |

Driver stage ready for operation |

|

10 |

Power |

green |

off |

The power supply voltage (24 VDC) is absent or the motor control is blocked (Index 6010:02] is not set)) |

|

on |

The power supply voltage (24 VDC) is present |

|||

|

11 |

Warning |

yellow |

on |

Configuration error, e.g.:

|

|

12 |

Error A |

red |

on |

Configuration error of output stage A, e.g.:

|

|

13 |

Error B |

red |

on |

Configuration error of output stage B, e.g.:

|

|

14 |

Enable |

green |

off |

The motor control is blocked (Index 6010:02] is not set) or SM-L15 is not ready for operation |

|

on |

The motor control is activated (Index 6010:02] is set) or SM-L15 is ready for operation |

|||

|

15 |

Turn CCW |

green |

on |

Motor is triggered counter clock wise |

|

16 |

Input 2 |

green |

on |

Signal at digital input 2 |

Terminal Points

|

Terminal point |

Name |

Signal |

|---|---|---|

|

1 |

A |

Encoder input A |

|

2 |

C |

Encoder input C (zero input). If object 7000:01 is set in the control word and a rising edge occurs at encoder input C, the current counter value is stored as a reference mark in the latch register. |

|

3 |

Encoder supply +24V |

Encoder supply + 24 V, internally connected with positive power contact and pin 6, 7 |

|

4 |

A1 |

Motor winding A1 |

|

5 |

B1 |

Motor winding B1 |

|

6 |

+24V |

+24 VDC, internally connected with positive power contact and pin 3, 7 |

|

7 |

+24V |

+24 VDC, internally connected with positive power contact and pin 3, 7 |

|

8 |

Input 1 |

Digital input 1 (24 VDC) |

|

9 |

B |

Encoder input B |

|

10 |

Latch |

Latch input. The current counter value is stored as a reference mark in the latch register, if |

|

11 |

Encoder supply 0V |

Encoder supply 0 V, internally connected with negative power contact and pin 14, 15 |

|

12 |

A2 |

Motor winding A2 |

|

13 |

B2 |

Motor winding B2 |

|

14 |

0V |

0 VDC, internally connected with negative power contact and pin 11, 15 |

|

15 |

0V |

0 VDC, internally connected with negative power contact and pin 11, 14 |

|

16 |

Input 2 |

Digital input 2 (24 VDC), also configurable as a digital output (0,5 A) |