Working With A Digitizing Axis in PLCopen

This topic provides the basics of setting up a digitizing axis and describes how to accomplish some common tasks. See Common Axis Parameters for reference material.

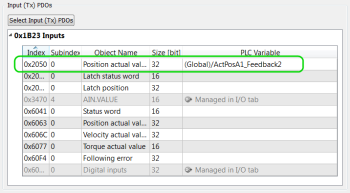

- A Digitizing Axis requires a feedback position. The feedback position can come from a secondary feedback of a drive or an EtherCAT

EtherCAT is an open, high-performance Ethernet-based fieldbus system. The development goal of EtherCAT was to apply Ethernet to automation applications which require short data update times (also called cycle times) with low communication jitter (for synchronization purposes) and low hardware costs device. Typically the AKD or S300

EtherCAT is an open, high-performance Ethernet-based fieldbus system. The development goal of EtherCAT was to apply Ethernet to automation applications which require short data update times (also called cycle times) with low communication jitter (for synchronization purposes) and low hardware costs device. Typically the AKD or S300 "Servostar 300 drive"

See Servo Drive in Glossary/S700

"Servostar 300 drive"

See Servo Drive in Glossary/S700 "Servostar 700 drive"

See Servo Drive in Glossary drives provide the feedback position via the CoE object 0x2050.

"Servostar 700 drive"

See Servo Drive in Glossary drives provide the feedback position via the CoE object 0x2050.

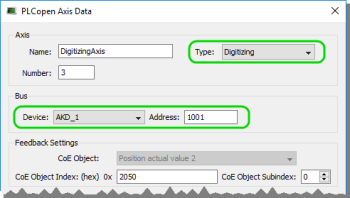

- The Digitizing Axis is created by setting the Type to "Digitiizing", selecting the EtherCAT device which will provide the feedback, and setting the correct CoE object.

- First generation AKD drives will use certain pre-set values.

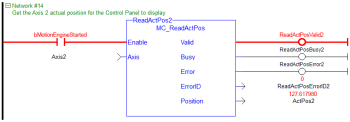

- The actual position in user units can be read with the MC_ReadActPos function block.

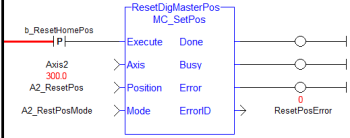

- The position can be offset using the MC_SetPos function block.

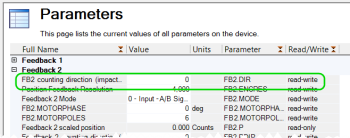

- For AKD drives, the polarity of the feedback signal can be changed using drive parameter FB2.DIR .

- If an Endat 2.2 device is being used, set FB3.DIR and change DRV.HANDWHEELSRC to 3 in order to tie the PDO index 2050 parameter that is read from FB2 to FB3.