Unwind – Registration – Rewind

4 axes with SFC![]() "Sequential function chart"

It can be used to program processes that can be split into steps.

The main components of SFC are:

- Steps with associated actions

- Transitions with associated logic conditions

- Directed links between steps and transitions/ST

"Sequential function chart"

It can be used to program processes that can be split into steps.

The main components of SFC are:

- Steps with associated actions

- Transitions with associated logic conditions

- Directed links between steps and transitions/ST![]() "Structured text"

A high-level language that is block structured and syntactically resembles Pascal and Pipe Network Motion Engine

"Structured text"

A high-level language that is block structured and syntactically resembles Pascal and Pipe Network Motion Engine

Introduction

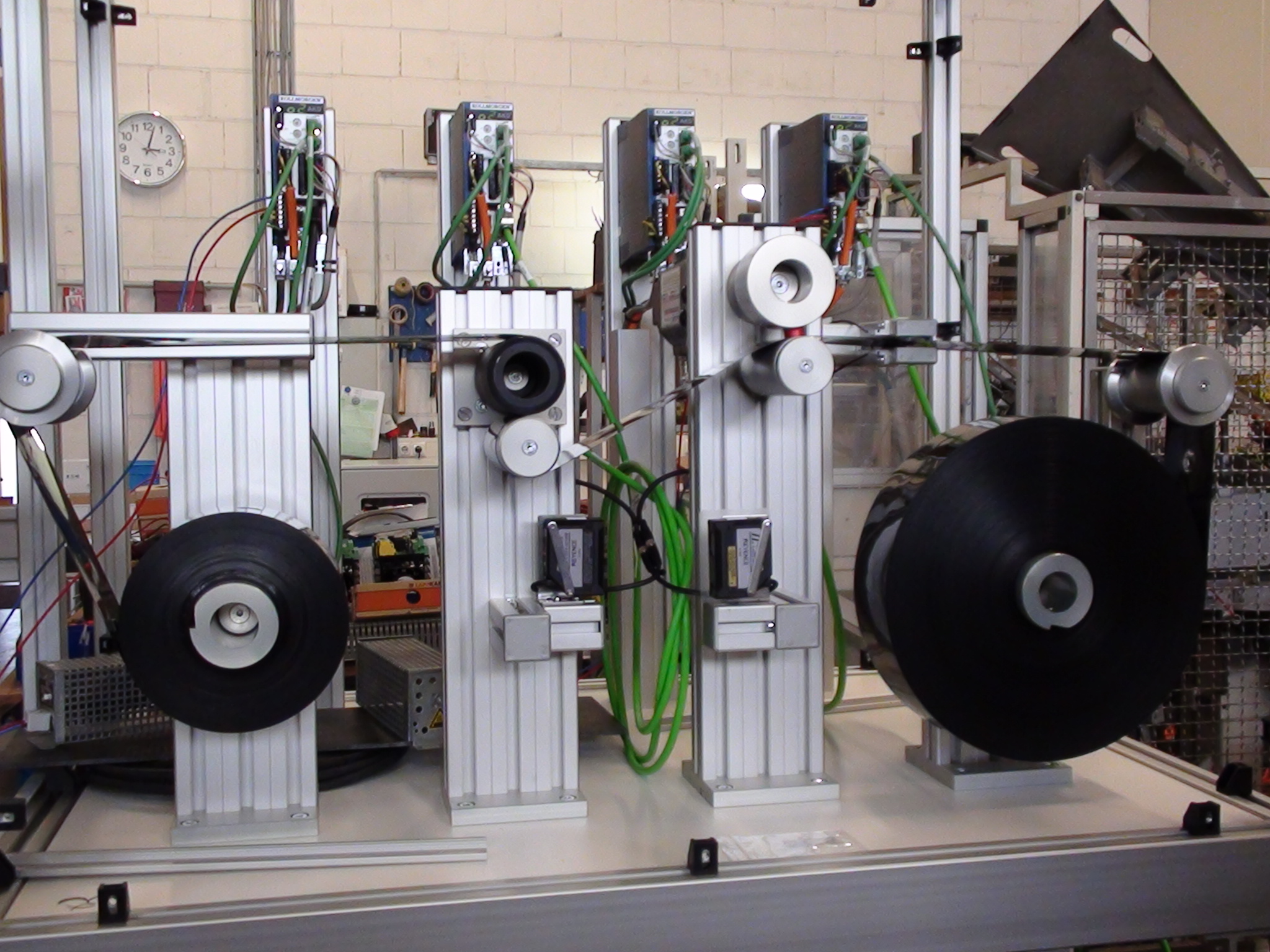

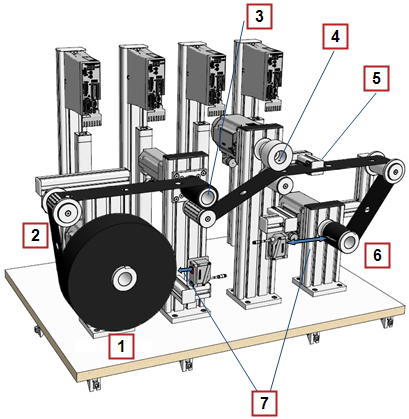

Machine Overview

This document details a KAS 4 axis unwind/rewind web system with a registration operation. The 4 axis are as follows:

- Axis 1: Left Unwind/ Rewind

- Axis 2: Draw Roller

- Axis 3: Die Cutter

- Axis 4: Right Unwind/Rewind

|

|

The machine can be run bi-directionally with the left roller as the unwind axis and right roller as the rewind axis or left roller as the rewind axis and right roller as the unwind axis. All four axes are tied to a virtual master using the KAS pipe network.

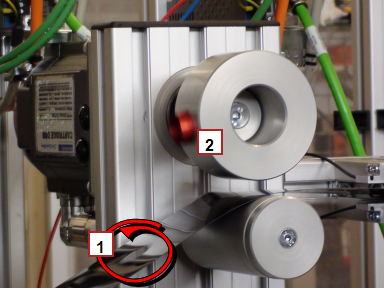

The web of material contains holes in it. The rotary die cutter axis is dynamically controlled to be in sync with the holes in the web.

|

|

The machine is run through a Kollmorgen AKI human machine interface:

There are multiple screens in the Kollmorgen AKI performing the following functions:

- Standby machine state

- Manual machine sate setup and operation

- Automatic machine state Setup and operation

- Servo drive status and fault clearing

- I/O status

- Alarm awareness

Control Overview

- KVB, PLC

"Programmable Logic Controller"

A Programmable Logic Controller, PLC, or Programmable Controller is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines.

Used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events and Motion programming in one controller

"Programmable Logic Controller"

A Programmable Logic Controller, PLC, or Programmable Controller is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines.

Used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events and Motion programming in one controller - 4 Axes synchronized motion (Pipe Network)

- 2 Unwinder / Rewinder (CDDR) (forward/backward)

- Draw Roller (AKM)

- Die-Cutter (CDDR)

- Unwinding and rewinding (100 m/min)

- No dancer necessary

- Tension controlled (250 µs)

F = const, M = f(r) - Acceleration feed-forward

This describes an element or pathway within a control system which passes a controlling signal from a source in the control system's external environment, often a command signal from an external operator, to a load elsewhere in its external environment (250 µs)

This describes an element or pathway within a control system which passes a controlling signal from a source in the control system's external environment, often a command signal from an external operator, to a load elsewhere in its external environment (250 µs)

M = a * I with I = f(r)

- Die-Cutter with changeover on the fly (150 mm … 600 mm)

- Registration mark control (compensates slippage of draw roller)