Feedback View

Feedback View

Each feedback device![]() A process whereby some proportion of the output signal of a system is passed (fed back) to the input.

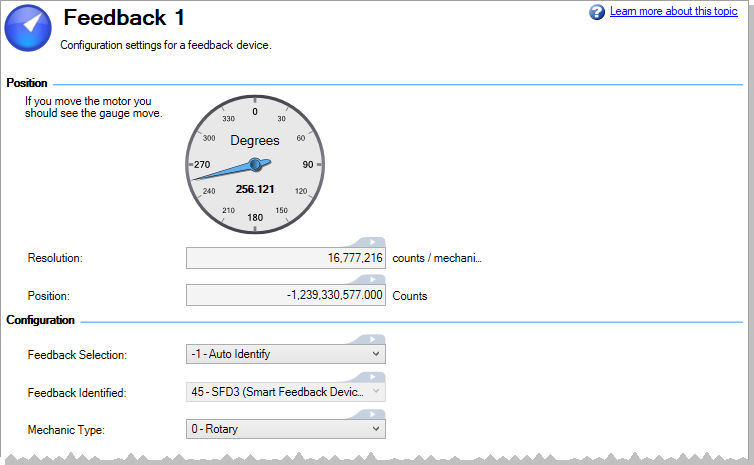

In automation, a device coupled to each motor to provide indication of the motor's shaft angle, for use in commutating the motor and controlling its speed and position has its own view for detailled configuration. This view is used to set up your system to match the proper feedback device. By default, the drive assigns Feedback 1 to Axis 1, Feedback 2 to Axis 2, and uses the Auto Identify setting to detect feedback devices. This setting allows the drive to test the feedback device to see if it is a recognized plug and play device. If the drive recognizes the device, then all parameters for that device and motor are loaded into the drive. Both the feedback and the motor information are now present in the drive and the system is operable.

A process whereby some proportion of the output signal of a system is passed (fed back) to the input.

In automation, a device coupled to each motor to provide indication of the motor's shaft angle, for use in commutating the motor and controlling its speed and position has its own view for detailled configuration. This view is used to set up your system to match the proper feedback device. By default, the drive assigns Feedback 1 to Axis 1, Feedback 2 to Axis 2, and uses the Auto Identify setting to detect feedback devices. This setting allows the drive to test the feedback device to see if it is a recognized plug and play device. If the drive recognizes the device, then all parameters for that device and motor are loaded into the drive. Both the feedback and the motor information are now present in the drive and the system is operable.

If the feedback is a non- plug and play device, then you can choose from the list of supported devices in the Feedback Selection list and enter the feedback settings manually. The following sections describe each supported device available in the Feedback Selection list and the input information required to configure each device.

FB#.INFO can be used to read additional information about the feedback when it is available.

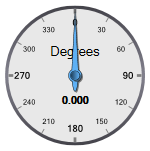

Position

This section of the Feedback view provides the current state of the feedback device.

| Element | Description | Parameter |

|---|---|---|

| Meter |

Provides live data showing the relative position within a revolution of the feedback device. The Mechanic Type setting determines whether the meter type.

|

|

| Resolution | Displays the resolution used for the device. Rotary devices are counts / mechanical revolution, linear devices are counts / pole. | FB#.RES |

| Position | Displays the raw position of the feedback device in counts. | FB#.P |

Configuration

This section of the Feedback view provides for defining the feedback device.

| Element | Description | Parameter |

|---|---|---|

| Feedback Selection | Specify the type of feedback automatically or manually. See Feedback Types below for a description of each type. | FB#.SELECT |

| Feedback Identified | This parameter is set according to FB#.SELECT on drive power up if FB#.SELECT is not –1. Otherwise the parameter value is read from the drive memory. | FB#.IDENTIFIED |

| Mechanic Type | Select whether the feedback is a rotary (0) or linear (1) encoder. | FB#.MECHTYPE |

| Encoder Resolution | Configure the number of lines per revolution for rotary encoders or the line pitch (nm/line) for linear encoders. | FB#.ENCLINES (for rotary) or FB#.LINEPITCH (for linear) |

| Multi-turn Sensor |

Number of multi-turn bits used for BiSS |

FB#.MULTITURNBITS |

| Single-turn Sensor Bits | Number of single turn bits used for BiSS rotary encoders. | FB#.SINGLETURNBITS |

| Feedback Poles | Sets the number of individual poles in a Resolver feedback device. This variable is used for the commutation function, as well as for velocity feedback scaling, and represents the number of individual poles (not pole pairs). | FB#.POLES |

| Transformation Ratio | Sets the Resolver nominal transformation ratio. It affects the resolver excitation output amplitude. | FB#.RESKTR |

| Phase Lag | Sets the electrical degrees of phase lag in the Resolver. | FB#.RESREFPHASE |

Feedback Types

| Value | Type | Description |

|---|---|---|

| -1 | Auto Identify | This is the default setting for Feedback 1 and 2 and is used to determine if a plug and play device is available. If a plug and play device is available, the FB#.IDENTIFIED keyword indicates the feedback device is detected. FB#.RES is updated with the resolution of the detected feedback. |

| 1 | No Encoder | This setting can be used if no feedback device is connected to the associated feedback connector. |

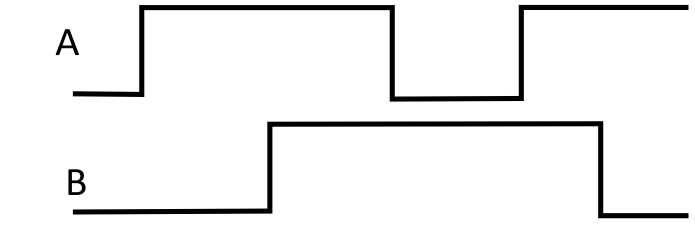

| 10 | Incremental Encoder with Halls |

Incremental encoders are available in a variety of line counts. If you select an incremental encoder option, the encoder resolution must be entered into the Encoder Resolution box or by setting FB#.ENCLINES. The units for this field are in lines per revolution. Wake and Shake will be enabled when using incremental encoders without Halls sensors.

|

| 11 | Incremental Encoder without Halls | |

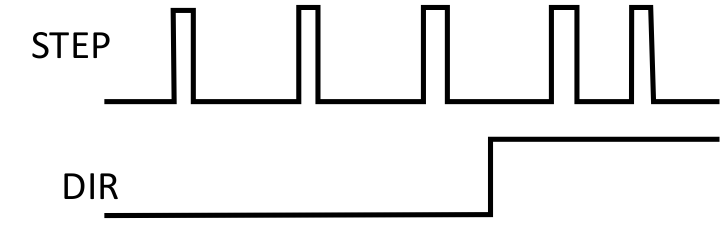

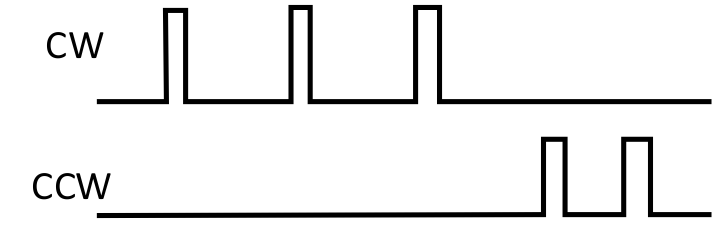

| 13 | Step / Direction |

This mode is intended to be used by controllers to provide a Electronic Gearing source signal. The A line pulses for each step and the B line indicates the direction. Encoder Resolution (FB#.ENCLINES) is used to configure how many pulses per revolution there are.

|

| 14 | CW / CCW |

As with Step/Direction, this mode is intended to be used as a Electronic Gearing source signal. The A line controls pulses in the clock wise direction and the B line control pulses in the counter-clockwise direction. Encoder Resolution (FB#.ENCLINES) is used to configure how many pulses per revolution there are.

|

| 20 | Sine Encoder with Halls | A sine-cosine uses a sine wave to indicate rotation. As with the incremental encoder, the line count is entered in the Encoder Resolution box or by setting FB#.ENCLINES. The actual resolution is much higher than the encoder line setting from measuring the analog signal. Wake and Shake will be enabled when using sine encoders without Halls sensors. |

| 21 | Sine Encoder without Halls | |

| 30 | EnDat 2.1 - Analog |

EnDat uses a sine encoder to indicate position with an analog signal. |

| 31 | EnDat 2.2 - Digital |

EnDat supports both digital only and sin/cos analog signals and may only support digital only depending on encoder model. |

| 34 | BiSS Mode C - Digital |

These feedback devices are all digital. See manufacturer specs for more information. |

| 40 | Resolver |

The resolver feedback is an analog signal. When selecting the resolver option, the resolver specific parameters phase lag, transformation ratio, and feedback poles are set for (Undefined variable: Primary.DriveVariant_AKM) motors.

|

| 41 | SFD (Smart Feedback Device |

Smart Feedback Device (SFD) is Kollmorgen's most popular plug and play device. SFD allows for quick and easy setup from the Auto mode, which automatically configures the drive with the motor and feedback parameters. SFD3 only requires 2 wires while SFD requires 4 wires. |

| 45 | SFD3 (Smart Feedback Device Gen3) | |

| 46 | HIPERFACE DSL |

These feedback devices are all digital. See manufacturer specifications for more information. |

Primary Feedback

The default source for Axis 1 is Feedback 1, and for Axis 2 is Feedback 2. This means only SFD3 and HIPERFACE DSL are supported by default. To use other feedbacks, AXIS#.IL.FBSOURCE must be changed to 3 for Feedback 3 and Feedback 3 must be setup for the desired feedback or SFA.

Dual-Loop

There are separate feedback sources for the current, velocity, and position loops. By default they’re all set to the current loop feedback source (AXIS#.IL.FBSOURCE). If a separate feedback is desired for the different loops, those sources can be set independently using AXIS#.VL.FBSOURCE and AXIS#.PL.FBSOURCE .

Electronic Gearing

For Electronic Gearing, AXIS#.GEAR.FBSOURCE is also available. See the Electronic Gearing feature for more information.