Description

VL.KP sets the proportional gain of the velocity loop.

The idealized velocity loop bandwidth![]() In computer networking, bandwidth often refers to a data rate measured in bits/s, for example, network throughput. The reason for the connection of data rate with the term bandwidth is that the limit to the data rate of a physical communication link is related to its bandwidth in hertz in Hz is:

In computer networking, bandwidth often refers to a data rate measured in bits/s, for example, network throughput. The reason for the connection of data rate with the term bandwidth is that the limit to the data rate of a physical communication link is related to its bandwidth in hertz in Hz is:

Rotary motor:

Where:

Kt= motor torque![]() Torque is the tendency of a force to rotate an object about an axis. Just as a force is a push or a pull, a torque can be thought of as a twist constant, in units of Nm/Arms

Torque is the tendency of a force to rotate an object about an axis. Just as a force is a push or a pull, a torque can be thought of as a twist constant, in units of Nm/Arms

Jm = motor inertia, in units of kg*m²

Linear motor:

Bandwidth (Hz) = VL.KP * Kt / (Motor Pitch (mm) * Jm)

Where:

Kt= motor torque constant, in units of Nm/Arms

Jm = motor inertia, in units of kg

The drive uses the same control loop for both linear and rotary motors. VL.KP units are in Arms /(rad/s). If you want to tune in units of Arms/(mm/s), then you must manually convert the units.

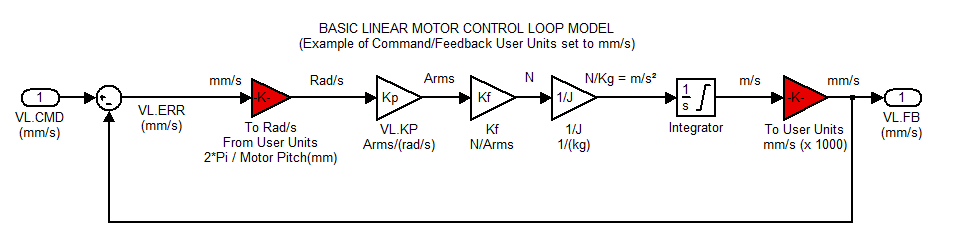

The diagram below shows how linear motors are implemented at the control loop level.

The red blocks are automatically handled at the drive level.

2π radians is the linear equivalent of one full mechanical revolution of a rotary motor - and is equal to the MOTOR.PITCH of a linear motor.

Example

To convert VL.KP = 0.320 Arms/(rad/s) to Arms/(mm/s), where MOTOR.PITCH is 32 mm:

VL.KP = 0.320 Arm /rad/s * (2π rad / 32mm MOTOR.PITCH)

VL.KP = 0.32 * 2π / 32 = 0.063 Arms / (mm/s)

General Information

|

Type |

NV Parameter |

|

Units |

A/(rad/sec) |

|

Range |

0.001 to 2,147,483.008 |

|

Default Value |

1 |

|

Data Type |

Float |

|

See Also |

|

|

Start Version |

M_01-00-00-000 |

|

Index/Subindex |

Object Start Version |

|

|---|---|---|

|

/0 |

M_01-00-00-000 |