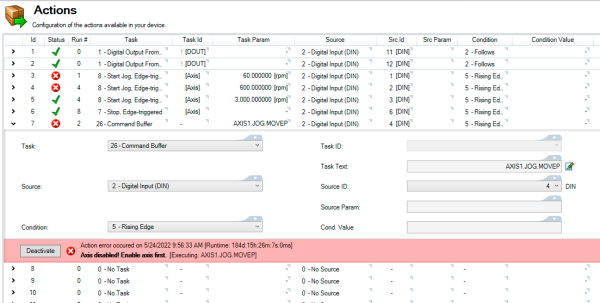

Actions Table

Actions Table

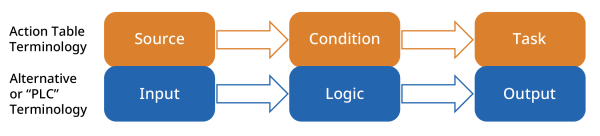

Use the Actions view to setup tasks for the drive to perform based on selected sources and conditions. Up to 32 actions can be configured. Each action, at a minimum, has three elements, of which may have additional requirements.

Action Table Terminology Compared to PLC Terminology

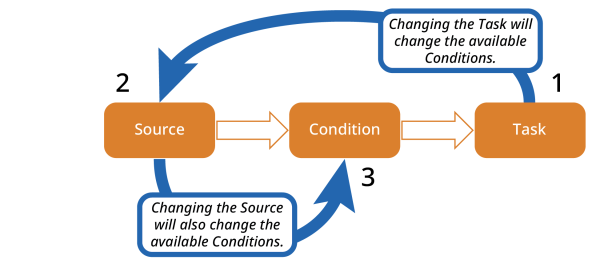

Action Configuration Order

The chosen Task determines both the available Source options and Condition options. The selected Source further affects available Condition options.

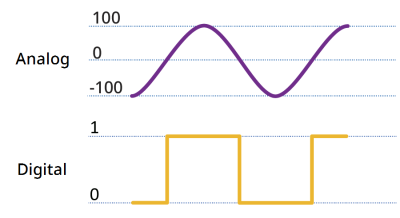

Input Signal Types

Input signals are either analog or digital. The AKD2G supports upto 12 digital inputs (DIN1-12) and 2 analog inputs (AIN1-2).

Input Signal Trigger Conditions

An Action Task is triggered when the source input signal meets the criteria of the selected condition.

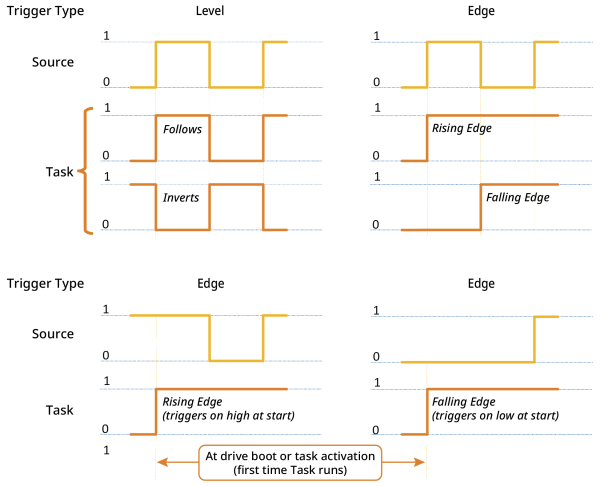

Digital Input Triggers

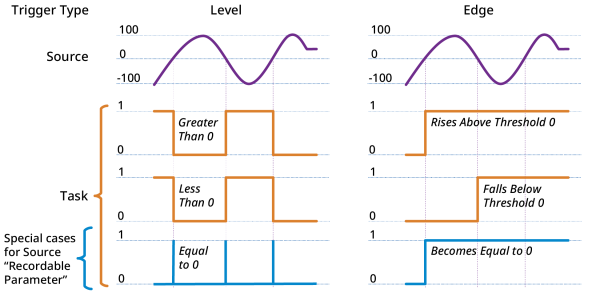

Analog Input Triggers

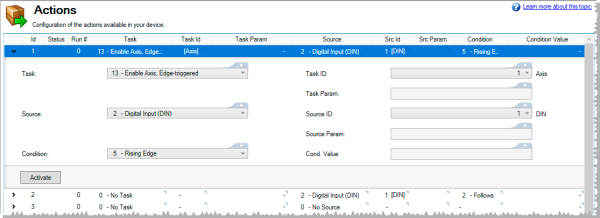

Action Example

Action 1 below attempts to Enable Axis 1 any time it is triggered by a on Digital Input 1. This action also has a Source ID setting which digital input to react on and a Task ID setting which axis to enable.

Action Execution

Actions are executed sequentially, top to bottom, starting at Action 1, at a 4kHz rate.

Certain tasks, like clearing faults, may take a longer than 4kHz cycle to execute. These tasks will be initiated in a low priority thread. If the task is triggered a second time while the task is already running, it will not be queued to run again and the action will be ignored until the running task is complete.

Scanning of the table does not begin until boot up has completed. Any edges occurring on any signal will be ignored until this time. In addition, edge triggered actions will not be executed if the test condition is already true at boot time.

To avoid inconsistent behavior, an action is automatically disabled when any of its fields are edited. Reactivate the action after editing any of its field settings.

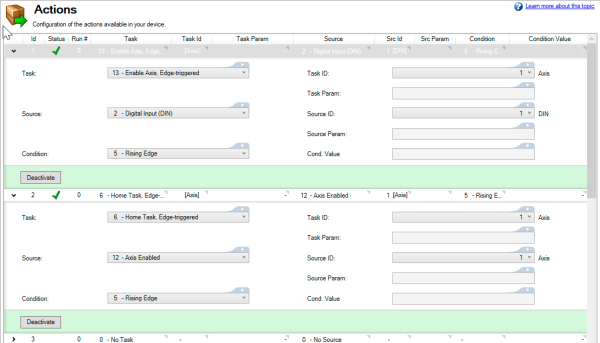

Chaining Actions

Actions are executed sequentially so they can be configured to execute a chain of actions.

For example, if Action 1 enables axis 1 when mains ready is true, then Action 2 can be configured to start homing when axis 1 is enabled. When Action 1 completes its task, it triggers Action 2 to execute.

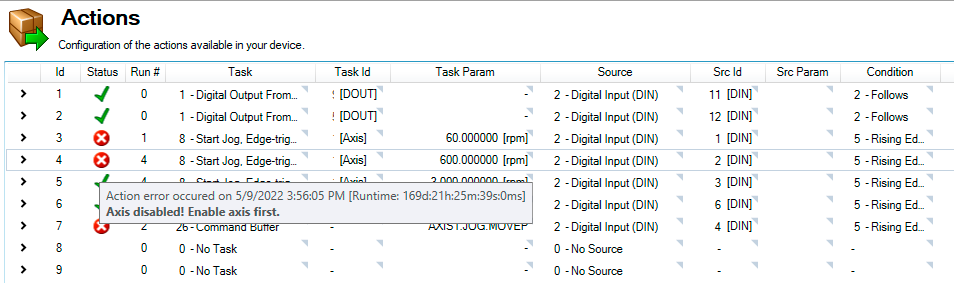

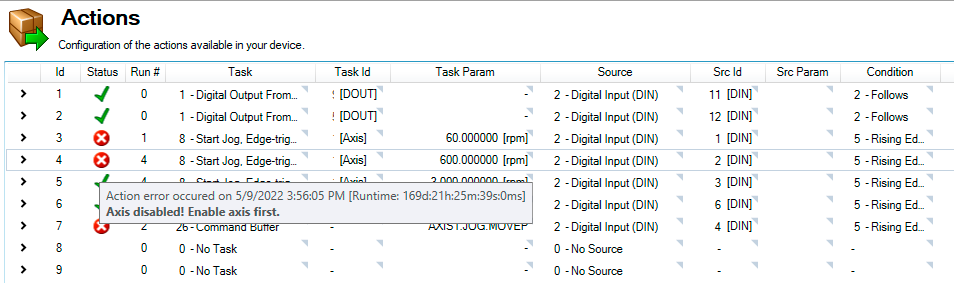

Action Errors

When an action error occurs, the Activate/Deactivate banner turns red and displays the error information along with the offending keyword, if applicable.

Error information may also be retrieved by clicking on the error symbol in the Status column.

Reference

| Element |

Description |

Parameter |

| Status |

Indicates whether an action is active, or experiencing an error. |

ACTION#.ACTIVE

ACTION#.ERROR

|

| Run# |

The Run# column displays the run count for each action. |

ACTION#.RUNCOUNT

|

| Task |

An action task defines the drive function to execute when the source's condition is met. Some tasks execute a drive function when the condition becomes true. Other tasks execute every cycle and use the condition or source to set a drive value.

| Value |

Description |

Signal Type |

| 0 |

No task |

N/A |

| 1 |

Digital Output from Source, Continuous |

Digital |

| 2 |

Set Digital Output, Edge-triggered |

Digital |

| 3 |

Clear Digital Output, Edge-triggered |

Digital |

| 5 |

Motion Task, Edge-triggered |

Digital |

| 6 |

Home Task, Edge-triggered. Homes based on the saved parameters on the drive |

Digital |

| 7 |

Stop, Edge-triggered |

Digital |

| 8 |

Start Jog, Edge-triggered |

Digital |

| 9 |

Controlled Stop, then disable with re-enable. Drive disables but SW disable bit is not set. If an active Task is disabled (or deactivated) CS bit is cleared and the drive is enabled. |

Digital |

| 10 |

Controlled Stop, then disable. Drive disables and SW disable bit is set. If an active Task is disabled (or deactivated) CS bit is cleared but the SW bit remains set and the drive remains disabled.

|

Digital |

| 11 |

Controlled Stop, and stay enabled. While this action is active then bit 1 in AXIS#.MOTIONDISSOURCES will be set. Drive remains enabled while motion stops. CS bit is not set. |

Digital |

| 12 |

Clear Faults, Edge-triggered

In addition to clearing the fault, this action sets the software enable to prevent the axis from immediately enabling.

See action task 28 to avoid the software enable set.

ACTION#.TASKID selects which axis the faults will be cleared on, zero will clear the faults on both axes.

|

Digital |

| 13 |

Enable Axis, Edge-triggered |

Digital |

| 15 |

Set Analog Output |

Analog |

| 16 |

Disable Axis, Edge-triggered |

Digital |

| 18 |

Activate Gearing, Edge-triggered |

Digital |

| 19 |

Add Gearing Position, Edge-triggered |

Digital |

| 20 |

Set Motion Task Feedrate |

Digital |

| 21 |

Digital DIO From Source, Continuous |

Digital |

| 22 |

Set Digital DIO, Edge-triggered |

Digital |

| 23 |

Clear Digital DIO, Edge-triggered |

Digital |

| 24 |

Fault Axis. When triggered, the selected axis will fault with F3006 (Action table fault) |

Digital |

| 25 |

Release brake on axis. While this action is active, the brake will be released on axis. |

Digital |

| 26 |

Command Buffer, Execute up to eight user defined commands. See Command Buffer for more details. |

Digital |

| 27 |

Set the Command Source and Op-Mode depending on value in the task parameter, Edge-triggered. |

Digital |

| 28 |

Clear Faults Software Enable Unchanged, Edge-triggered

This action clears any faults on the axis and will not set the software enable. The axis immediately enables after the fault is cleared when using this action task. When using the AKD2G drive with wired digital inputs,it is convenient to clear faults and not have the drive set the software enable automatically.

See action task 12 for the software enable set when faults are cleared.

ACTION#.TASKID selects which axis the faults will be cleared on, zero clears the faults on both axes.

|

Digital |

| 29 |

Motion Task Select Bit, Continuous

This task is used to select the motion task id for action task 30 (Motion Task Start Selected) to run. For example:

IF

ACTION1.TASK = 29 (Motion Task Select Bit), ACTION1.SOURCE = 2 (DIN), ACTION1.SOURCEID = 2, ACTION1.TASKID = 1 (Axis 1), and ACTION1.TASKPARAM = 2 (MT Select Bit)

AND

ACTION2.TASK = 29 (Motion Task Select Bit), ACTION2.SOURCE = 2 (DIN), ACTION2.SOURCEID = 3, ACTION2.TASKID = 1 (Axis 1), and ACTION2.TASKPARAM =3 (MT Select Bit)

THEN

AXIS#.MT.ACTIONSELECTED will be set to 12 when both DIN 2 and 3 are high.

|

Digital |

| 30 |

Motion Task Start Selected, Edge-triggered

This task runs the motion task selected by task 29 (Motion Task Select Bit). AXIS#.MT.ACTIONSELECTED holds the current MT index that will run.

A rising edge starts the motion task. A falling edge has no effect.

|

Digital |

s

|

ACTION#.TASK

|

| Task ID |

Some tasks require the Task ID to specify what is acted upon such as setting a DOUT value. |

ACTION#.TASKID

|

| Task Param. |

Some tasks require task parameters to further specify what is acted on. For example, if the task is Motion Task, Edge-triggered the task parameter field appears. Setting this field to 5 specifies the action starts motion task 5 on the selected axis.

|

ACTION#.TASKPARAM

|

| Source |

The action source is the input to which the drive reacts.

| Value |

Name |

Description |

Signal Type |

| 0 |

No source |

Default value of no specified source |

N?A |

| 1 |

Mains ready |

This digital source goes high when the bus voltage is available to the drive. It does not take any ID or parameters. |

Digital |

| 2 |

Digital Input |

This digital source corresponds to a DIN. It takes an ID. |

Digital |

| 3 |

Digital Dio (Bidirectional) |

This digital source corresponds to DIO. It takes an ID. |

Digital |

| 4 |

Velocity Feedback |

This analog source holds the value of AXIS#.VL.FB

. It takes an axis ID. |

Analog |

| 5 |

Axis Faulted |

This digital source goes high when a fault exists on an axis. It takes an axis ID. |

Digital |

| 6 |

Home Complete |

This digital source is high when a Home operation is completed on an axis. It takes an axis ID. |

Digital |

| 7 |

Motion Task in Position |

This digital source is high when on an axis specified by the axis ID, a MotionTask specified by Source Parameter, has reached its position. It takes both ID and parameter. |

Digital |

| 8 |

Controlled Stop Active |

This digital source is high when a Controlled Stop is active on an axis. It takes an axis ID. |

Digital |

| 9 |

Software Limit |

This digital source is high when a software limit on an axis is reached. It takes an axis ID. |

Digital |

| 10 |

MT Not Running |

This digital source is high if, on the axis specified by the source ID, either the Motion Task specified by the source parameter has stopped running (i.e. AXIS#.MT.RUNNING for that task went from 1 to 0) or, if the source parameter is set to -1, all Motion Tasks have stopped running (i.e. AXIS#.MT.RUNNINGTASK went from any other value to -1). This source does not check whether the actual position has reached the Motion Task’s target position. |

Digital |

| 11 |

Position Error, Absolute |

This analog source holds the value of AXIS#.PL.ERR

. It takes an axis ID. |

Analog |

| 12 |

Axis Enabled |

This digital source holds the value of AXIS#.ACTIVE . It takes an axis ID. |

Digital |

| 13 |

Analog Input |

This analog source holds the value of AIN#.VALUE. It takes as Source ID, the ID of AIN. |

Analog |

| 14 |

Current Command |

This analog source holds the value of AXIS#.IL.CMD . It takes an axis ID. |

Analog |

| 15 |

Velocity Error |

This analog source holds the value of AXIS#.VL.ERR

. It takes an axis ID. |

Analog |

| 16 |

Velocity Command |

This analog source holds the value of AXIS#.VL.CMD. It takes an axis ID. |

Analog |

| 17 |

Position Feedback |

This analog source holds the value AXIS#.PL.FB

. It takes an axis ID. |

Analog |

| 18 |

Axis Disable Immediately |

This digital source goes high when the power stage is disabled or dynamic braking is applied. It takes an axis ID. |

Digital |

| 19 |

Brake State |

This digital source holds the value of BRAKE#.STATE. It takes a Brake ID. |

Digital |

| 20 |

Ready to Operate (RTO/BTB) |

This digital source goes high when the drive/axis is ready to operate, i.e., the power stage is ready and there are no axis faults. It can default to an ID of 0 for the entire drive or take an axis ID. |

Digital |

| 21 |

Compare Digital Inputs |

This bit-mapped source shows the value of all the DINs and DIOs compared with a mask which is settable with UI. |

Digital |

| 22 |

Feedback Fault |

This source holds the value of FB#.FAULTBITS. It takes a Feedback ID. |

Digital |

| 23 |

User Variable |

This source holds the value of USER.INT#. It takes an ID. |

Analog |

| 24 |

Action Row Running |

This digital source indicates if an Action Row is running, i.e. if the task is being executed (see ACTION.RUNNING). It takes an Action Row ID. |

Digital |

| 25 |

Current Feedback |

This analog source holds the value of AXIS#.IL.FB . It takes an axis ID. |

Analog |

| 26 |

Recordable Parameter |

This allows an action to be triggered by using any Recordable Parameter. When selected, the Source Text window now accepts an array parameter keyword and index. 26 – Recordable Parameter |

Analog |

| 27 |

Drive Initialized |

This digital source goes high when the drive has finished initialization after booting. |

Digital |

| 28 |

Move Complete |

This digital source is high if, on the axis specified by the source ID, either the motion task specified by the source parameter has stopped running (i.e. AXIS#.MT.RUNNING for that task went from 1 to 0) and the actual position is within AXIS#.SETTLE.P around the motion task’s target position or, if the source parameter is set to -1, all motion tasks have stopped running (i.e. AXIS#.MT.RUNNINGTASK went from any other value to -1) and the actual position is within AXIS#.SETTLE.P around the last motion task’s target position. It will only go low when the motion task is started again, not if the actual position is no longer within AXIS#.SETTLE.P around the target position. |

Digital |

| 200 |

Safe Input |

|

|

| 201 |

Safe Dual Input |

|

|

| 202 |

Safe Output |

|

|

| 203 |

Safe Dual Output |

|

|

| 204 |

STO active |

|

|

| 205 |

SS1 active |

|

|

| 206 |

SS2 active |

|

|

| 207 |

SOS active |

|

|

| 208 |

SBC active |

|

|

| 209 |

SLS active |

|

|

| 210 |

SSM active |

|

|

| 211 |

SSR active |

|

|

| 212 |

SDI_n active |

|

|

| 213 |

SDI_p active |

|

|

| 214 |

SLA active |

|

|

| 215 |

SAR active |

|

|

| 216 |

SLI active |

|

|

| 217 |

SLP active |

|

|

| 218 |

SCA active |

|

|

|

ACTION#.SOURCE

|

| Source ID |

Some action sources require a specific Source ID number such as a DIN value. |

ACTION#.SOURCEID

|

| Source Param. |

Some sources require source parameters to further specify what is acted on. For example, if the source is Move Complete, the source parameter field becomes editable. Setting this field to 8 specifies the action considers Move Complete for motion task 8 on the selected axis.

|

ACTION#.SOURCEPARAM

|

| Source Text |

The Source Text field allows the user to enter an array parameter keyword and index.

|

ACTION#.SOURCETEXT

|

| Condition |

A condition value is required when the condition performs a comparison. For example, if the action source is set to Analog Input, and the condition is set to "Falls Below Threshold", a condition value defines the threshold. If the condition value is set to 4.5, the action checks if the analog input transitions from a value greater than 4.5 volts to a value less than 4.5 volts.

| Digital Source |

Analog Source |

Trigger Type |

| Follows |

Greater than |

Level |

| Inverts |

Lesser than |

Level |

|

|

Rises Above Threshold |

Edge |

| Falling Edge |

Falls Below Threshold |

Edge |

| Rising Edge (Triggers on High at Start) |

|

|

| Falling Edge (Triggers on Low at Start) |

|

|

|

ACTION#.CONDITION

|

| Condition Value |

Defines the value used by the Condition to test against the Source. |

ACTION#.CONDITIONVALUE

|

Actions Table

Actions Table![]() A rising edge is the transition of a digital signal from low to high. It is also called positive edge on Digital Input 1. This action also has a Source ID setting which digital input to react on and a Task ID setting which axis to enable.

A rising edge is the transition of a digital signal from low to high. It is also called positive edge on Digital Input 1. This action also has a Source ID setting which digital input to react on and a Task ID setting which axis to enable.