![]()

![]()

Function

Function![]() A function calculates a result according to the current value of its inputs.

A function has no internal data and is not linked to declared instances. - Initializes the motion library.

A function calculates a result according to the current value of its inputs.

A function has no internal data and is not linked to declared instances. - Initializes the motion library.

Inputs

|

Input |

Data Type |

Range |

Unit |

Default |

Description |

|---|---|---|---|---|---|

|

BOOL |

TRUE, FALSE |

N/A |

FALSE |

Enable function. |

|

|

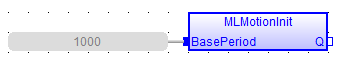

BasePeriod |

LREAL |

Minimum: 125 |

Microseconds |

1000 |

Duration of one motion cycle.

|

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

Q |

BOOL |

TRUE, FALSE |

N/A |

|

Remarks

- Must be called before any other Motion Library function.

- Returns TRUE if the function succeeded.

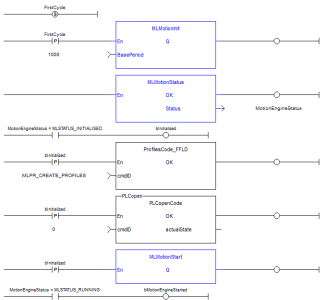

FBD Language Example

FFLD Language Example

IL Language Example

Not available.

ST Language Example

//Initialization code to start EtherCAT network.

//First initialize network with MLMotionInit command

//Then wait for command to finish by monitoring MLMotionStatus output

//Once initialized, create any cam profilesThe position of a slave axis is mathematically linked to the position of a master axis. Example: A system where two rotating drums turn at a given ratio to each other. A more advanced case of electronic gearing is electronic camming. With electronic camming, a slave axis follows a profile that is a function of the master position. This profile need not be linear but it must be a mathematical function. and PLCopen

A vendor -and product- independent worldwide association active in Industrial Control and aiming at standardizing PLC file formats based on XML. or Pipenetwork devices

//Then call MLMotionStart and monitor MLMotionStatus again before beginning rest of programThe act of performing a sequence of instructions or commands.

FirstCycle := TRUE;

On FirstCycle DO //Initialize the motion engine

MLMotionInit( 1000);

END_DO;

MotionEngineStatus := MLMotionStatus();//Check the current status of the motion engine

//Once motion engine is initialized, create CAM profiles and defined Axis, then start the motion engine

ON MotionEngineStatus = MLSTATUS_INITIALISED DO

Profiles( MLPR_CREATE_PROFILES );

PLCopen( 0 );

MLMotionStart();

END_DO;

IF MotionEngineStatus = MLSTATUS_RUNNING THEN

bMotionEngineStarted := TRUE;

ELSE

bMotionEngineStarted := FALSE;

END_IF;