![]()

Function

Function![]() A function calculates a result according to the current value of its inputs.

A function has no internal data and is not linked to declared instances. - Creates a PLCopen

A function calculates a result according to the current value of its inputs.

A function has no internal data and is not linked to declared instances. - Creates a PLCopen![]() A vendor -and product- independent worldwide association active in Industrial Control and aiming at standardizing PLC file formats based on XML. Axis.

A vendor -and product- independent worldwide association active in Industrial Control and aiming at standardizing PLC file formats based on XML. Axis.

Inputs

|

Input |

Data Type |

Range |

Unit |

Default |

Description |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

En |

BOOL |

0, 1 |

N/A |

No default |

Requests to create a PLCopen axis. |

||||||||||||

|

AxisName |

STRING |

No range |

N/A |

No default |

Axis name. |

||||||||||||

|

BusInterface |

STRING |

No range |

N/A |

No default |

Bus interface identifier:

|

||||||||||||

|

BusAddress |

DINT |

Bus dependent |

N/A |

No default |

|||||||||||||

|

AxisNumber |

UINT |

1, 256 |

N/A |

No default |

Axis number. |

||||||||||||

|

AxisType |

USINT |

0, 1 |

N/A |

No default |

|

||||||||||||

|

DriveAxisNumber |

UINT |

1, 256 |

N/A |

No default |

This one-based number specifies the axis on the drive. For a single-axis drive this number should be 1. |

||||||||||||

|

UserUnits |

DINT |

1, 2147483647 |

User units |

No default |

User unit portion of the user unit/feedback unit ratio. |

||||||||||||

|

FeedbackUnits |

DINT |

1, 2147483647 |

Feedback units |

No default |

Feedback unit portion of the user unit/feedback unit ratio. |

||||||||||||

|

Rollover |

LREAL |

0, 4294967296 |

User units |

No default |

Rollover position. 0 (zero) = no rollover. |

||||||||||||

|

UpdateRate |

UINT |

3, 9 |

N/A |

No default |

Servo update rate.

|

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

OK |

BOOL |

No range |

N/A |

Indicates the axis has been created. |

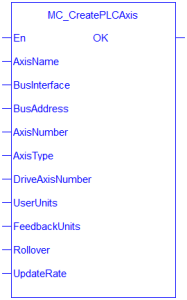

Figure 1: MC_CreatePLCAxis

Remarks

- See Function Blocks - General Rules about how inputs and outputs work.

- A call to this function is automatically generated when the application is compiled, based on the data entered in the PLCopen Axis Data dialog.

- MC_CreateAxis must be called between MLMotionInit and MLMotionStart.

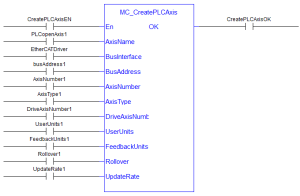

FBD Language Example

FFLD Language Example

IL Language Example

Not available.

ST Language Example

(* MC_CreatePLCAxis STStructured text - A high-level language that is block structured and syntactically resembles Pascal. Example *)

AxisName1 := 'PLCOpenAxis1';

BusName1 := 'EtherCATDriver';

BusAddress1 := 1001;

AxisNumber1 := 1;

AxisType1 := MC_AXIS_TYPE_SERVO_STEPPER;

DriveAxisNumber1 := 1;

UserUnits1 := 360;

FeedbackUnits1 := 1048576;

Rollover1 := 0;

UpdateRate1 := 3;

MC_CreateAxis(AxisName1, BusName1, BusAddress1, AxisNumber1, AxisType1, DriveAxisNumber1, UserUnits1, FeedbackUnits1, Rollover1, UpdateRate1);