AXIS#.MOTOR.IMID

Description

This parameter is the preset rotor flux building current for closed loop![]() The use of feedback devices (encoders, resolvers, interferometers, etc.) to allow a motor to position a user payload accurately. induction motor control (AXIS#.MOTOR.TYPE

= 4).

The use of feedback devices (encoders, resolvers, interferometers, etc.) to allow a motor to position a user payload accurately. induction motor control (AXIS#.MOTOR.TYPE

= 4).

The value of AXIS#.IL![]() "Instruction list"

This is a low-level language and resembles assembly.IMID can be estimated using the motor name plate information.

"Instruction list"

This is a low-level language and resembles assembly.IMID can be estimated using the motor name plate information.

The following rule should generally be used:

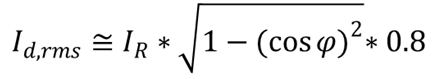

In which Id is the value for AXIS#.IL.IMID, the preset rotor flux building current, Ir is the name plate phase current, cosϕ is the name plate power factor at rated and operation, and 0.8 is an empirical factor (accounts for the angle error due to voltage drop on the leakage induction).

-

-

This parameter is required to be configured for AXIS#.MOTOR.TYPE = 4

Context

For more information see Motor.

Versions

| Action | Version | Notes |

|---|---|---|

| Implemented | 02-00-00-000 |

General Information

|

Type |

Read/Write |

|

Units |

Arms |

|

Range |

0 to DRIVE.IPEAK |

|

Default Value |

0 |

|

Data Type |

Float |

|

Stored in Non Volatile Memory |

Yes |

Variants Supported

All variants are supported.

Fieldbus Information

| Fieldbus |

Parameter | Index | Sub-Index | Data Type | Float Scale | Units | Access | PDO |

|---|---|---|---|---|---|---|---|---|

| EtherCAT |

AXIS1.MOTOR.IMID | 0x500B | 0xA | UINT | 1000:1 | - | RW | False |

| AXIS2.MOTOR.IMID | 0x510B | 0xA | UINT | 1000:1 | - | RW | False |