EtherNet/IP Tag Client

The KAS Runtime![]() In computer science, runtime (or run-time) describes the operation of a computer program, the duration of its execution, from beginning to termination (compare compile time).

Within KAS, runtime also refers to the virtual machine that manage the program written in a computer language while it is running includes fully integrated EtherNet/IP client driver for exchanging tags with EtherNet/IP tag based devices such as PLCs.

In computer science, runtime (or run-time) describes the operation of a computer program, the duration of its execution, from beginning to termination (compare compile time).

Within KAS, runtime also refers to the virtual machine that manage the program written in a computer language while it is running includes fully integrated EtherNet/IP client driver for exchanging tags with EtherNet/IP tag based devices such as PLCs.

Data exchange - Configuration

A dedicated configuration tool is integrated in the KAS-IDE![]() "Integrated development environment"

An integrated development environment is a type of computer software that assists computer programmers in developing software.

IDEs normally consist of a source code editor, a compiler and/or interpreter, build-automation tools, and a debugger.

"Integrated development environment"

An integrated development environment is a type of computer software that assists computer programmers in developing software.

IDEs normally consist of a source code editor, a compiler and/or interpreter, build-automation tools, and a debugger.

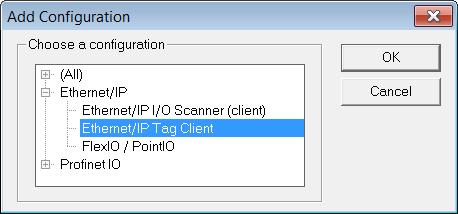

- Double-click the Fieldbus

A Fieldbus is an industrial network system for real-time distributed control (e.g. CAN or Profibus). It is a way of connecting instruments in a plant design node in the project explorer to open it.

A Fieldbus is an industrial network system for real-time distributed control (e.g. CAN or Profibus). It is a way of connecting instruments in a plant design node in the project explorer to open it. - Click the Insert Configuration icon

to add the Fieldbus configuration.

to add the Fieldbus configuration. - Select the EtherNet/IP Tag Client in the configuration selector.

The configuration is represented as a tree:

- EtherNet/IP Tag Client

- Server (an EtherNet/IP adapter device) (*)

- Tag (generally an array) (*)

- Exchanged variable (*)

- Exchanged variable (*)

- Tag (generally an array) (*)

(*) The items with this mark can appear several times in the configuration.

- Server (an EtherNet/IP adapter device) (*)

Driver![]() In computing and electronics, a driver is a software component allowing higher-level computer programs to interact with a computer hardware device.

A driver typically communicates with the device through the computer bus or communications subsystem to which the hardware is connected and configurator are optimized for exchanging arrays (tags declared as arrays in the PLC

In computing and electronics, a driver is a software component allowing higher-level computer programs to interact with a computer hardware device.

A driver typically communicates with the device through the computer bus or communications subsystem to which the hardware is connected and configurator are optimized for exchanging arrays (tags declared as arrays in the PLC![]() "Programmable Logic Controller"

A Programmable Logic Controller, PLC, or Programmable Controller is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines.

Used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events). However it is also possible to exchange single tags.

"Programmable Logic Controller"

A Programmable Logic Controller, PLC, or Programmable Controller is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines.

Used to synchronize the flow of inputs from (physical) sensors and events with the flow of outputs to actuators and events). However it is also possible to exchange single tags.

Configuration

Click the Insert Master icon  to declare an server (slave device). Each server is identified by its IP address and an optional description text.

to declare an server (slave device). Each server is identified by its IP address and an optional description text.

Then you need to configure tags such as declared in the PLC:

- The easiest way is to right-click on the server in the tree and select the Add ARRAY Tag command in the contextual menu. Then you enter the properties of the tag request and the symbol of the corresponding array to be used in your IEC

"International Electrotechnical Commission"

IEC is a not-for-profit, non-governmental international standards organization that prepares and publishes International Standards for all electrical, electronic and related technologies 61131-3 application. Configuration of the tag and mapping of all array items is performed automatically.

"International Electrotechnical Commission"

IEC is a not-for-profit, non-governmental international standards organization that prepares and publishes International Standards for all electrical, electronic and related technologies 61131-3 application. Configuration of the tag and mapping of all array items is performed automatically. - Alternatively, click the Insert Slaver icon

to declare the tag and map some variables later on.

to declare the tag and map some variables later on.

A tag request is identified by:

| Identifier | Meaning |

|---|---|

|

Tag name |

The name of the tag such as declared in the PLC. |

|

PLC Slot |

PLC slot number |

|

Mode |

Read or Write The same tag can be configured twice for both reading and writing. |

|

Nb Elements |

Number of array items to read or write. |

|

Offset |

O-based index of the first item to read or write in the array. |

|

Tag data type |

Data type of the tag such as declared in the PLC. Available Types are:

|

|

Period(ms) |

Specify in this parameter a period for continuously sending the request. Enter 0 (zero) for a request sent on-demand. |

|

Timeout |

Request timeout in milliseconds. |

IEC61131-3![]() IEC 61131-3 is the third part of the open international standard IEC 61131. The current (second) edition was published in 2003.

IEC 61131-3 currently defines five programming languages for programmable control systems

It deals with programming languages and defines two graphical and two textual PLC programming language standards variables are mapped on the data of the tag.

IEC 61131-3 is the third part of the open international standard IEC 61131. The current (second) edition was published in 2003.

IEC 61131-3 currently defines five programming languages for programmable control systems

It deals with programming languages and defines two graphical and two textual PLC programming language standards variables are mapped on the data of the tag.

For each variable you must specify:

| Identifier | Meaning |

|---|---|

|

Symbol |

The name of the IEC 61131-3 variable. |

|

Offset |

Offset in bytes in the assembly data. |

|

Bit |

Bit offset in the selected byte if format is Bit. |

|

Format |

Format of the data in the assembly. |

|

Mode |

The kind of data exchanged through the variable:

|

The tag is read or written:

- periodically if a non zero period is specified in the tag configuration.

- when a variable configured as "Send Request Now" becomes TRUE.

In the case of a command variable, the variable is automatically reset to FALSE when the request is sent.

-

-

The data limit is: 500 bytes of data maximum O(originator)->T(target) and 500 bytes of data maximum T(target) -> O(originator).

This is based on the Ethernet Ethernet is a large, diverse family of frame-based computer networking technologies that operate at many speeds for local area networks (LANs)/IP specification.

Ethernet is a large, diverse family of frame-based computer networking technologies that operate at many speeds for local area networks (LANs)/IP specification.