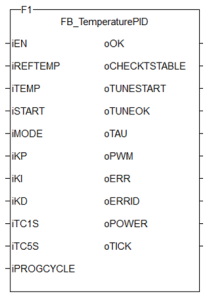

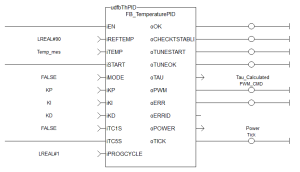

FB_TemperaturePID

Function Block - Provides PID temperature control with auto tuning.

Function Block - Provides PID temperature control with auto tuning.

Inputs

|

Input |

Data Type |

Range |

Unit |

Default |

Description |

|---|---|---|---|---|---|

|

iEN |

BOOL |

|

|

|

Enable function. |

|

iREFTEMP |

LREAL |

|

|

|

Reference temperature [°C]. |

|

iTEMP |

LREAL |

|

|

|

Actual temperature [°C]. |

|

iSTART |

BOOL |

|

|

|

Start PID or auto tuning. |

|

iMODE |

BOOL |

|

|

|

|

|

iKP |

LREAL |

|

|

|

PID Proportional Gain. |

|

iKI |

LREAL |

|

|

|

PID Integral Gain. |

|

iKD |

LREAL |

|

|

|

PID Derivative Gain. |

|

iTC1S |

BOOL |

|

|

|

Sampling Time is 1s. |

|

iTC5S |

BOOL |

|

|

|

Sampling Time is 5s. |

|

iPROGCYCLE |

LREAL |

|

|

|

Execution time of the function [ms]. |

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

oOK |

BOOL |

|

|

Function enabled. |

|

oCHECKSTABLE |

BOOL |

|

|

TRUE when checking if ambient temperature is stable. |

|

oTUNESTART |

BOOL |

|

|

Tuning is started. |

|

oTUNEOK |

BOOL |

|

|

Tuning is completed. |

|

oTAU |

LREAL |

|

|

System Time Constants. |

|

oPWM |

BOOL |

|

|

PWM command for heater. |

|

oERR |

BOOL |

|

|

Function error. |

|

oERRID |

INT |

|

|

Function ID error (in case of oERR=TRUE). |

|

oPOWER |

LREAL |

|

|

% of power requested from heater (100%=full power). |

|

oTICK |

BOOL |

|

|

Pulse every sampling time. |

Remarks

Figure 1: FB_TemperaturePID

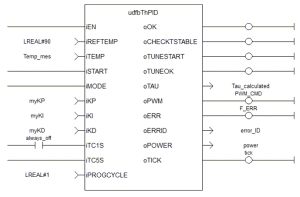

Usage

Tuning Process

Figure 2: FB_TemperaturePID Usage 1

Tuning Procedure

- Verify the ambient temperature is stable.

The measured delta_temp=Tmax-Tmin must be lower than 0.1*Tmax.

This step takes 10 cycles (10*iTC5s or 10*iTC1s).

The tuning fails (oERR=TRUE, oERRID=1) if the ambient temperature is greater than 0.1*Tmax, otherwise Tamb=(Tmax+Tmin)/2.- Start tuning Phase1: output oPWM is kept TRUE until the final measured temperature iTEMP gets over iREFTEMP/2.

After that, oPWM is kept LOW.- Start tuning Phase2.

With oPWM kept LOW, the temperature gets down until the final value is lower than [(iREFTEMP/2-Tamb)*0.368+Tamb].

After, PID gains are calculated as:

Kp=10

Ki=0.14

delta_time = time to complete Phase2 Kd=SQRT(delta_time)*7

The tuning is completed.

-

-

oTAU may be useful for setting the proper sampling time (1s or 5s).

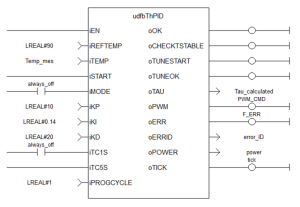

Start PID Controller

Figure 3: FB_TemperaturePID Usage 2

- When starting the PID controller:

- The output oPWM is modulated five times within the sampling time (blue line is oTICK, green line is oPWM).

- Each pulse length depends on output oPOWER (100%=full length).

Figure 4: FB_TemperaturePID Usage 3

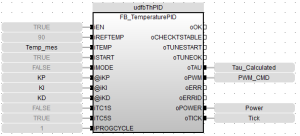

FBD Language Example

FFLD Language Example

IL Language Example

Not available.

ST Language Example

//Run PID function with determined proportional, integral, and derivative gains

//send PWM output to command heater

udfbThPID( TRUE, 90, Temp_mes, TRUE, FALSE, KP, KI, KD, FALSE, TRUE, 1);

Tau_Calculated := udfbThPID.oTAU;

PWM_CMD := udfbThPID.oPWM;

Power := udfbThPID.oPOWER;

Tick := udfbThPID.oTICK;