![]()

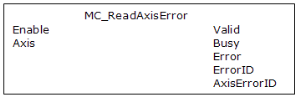

Function Block - Returns the error status of the specified axis.

Function Block - Returns the error status of the specified axis.

Inputs

|

Input |

Data Type |

Range |

Unit |

Default |

Description |

|---|---|---|---|---|---|

|

Enable |

BOOL |

FALSE, TRUE |

N/A |

No default |

Request to read the error status of the axis. |

|

Axis |

AXIS_REF |

1 to 256 |

N/A |

No default |

Name of a declared instance of the AXIS_REF library function.

|

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

Valid |

BOOL |

FALSE, TRUE |

N/A |

Indicates the AxisErrorID output is valid. |

|

Busy |

BOOL |

FALSE, TRUE |

N/A |

Indicates this function block is executing. |

|

Error |

BOOL |

FALSE, TRUE |

N/A |

Indicates an invalid input was specified. |

|

ErrorID |

INT |

-32768 to +32767 |

|

Indicates the error if Error output is TRUE. |

|

AxisErrorID |

INT |

-32768 to +32767 |

|

Indicates the error status of the axis.

|

Remarks

-

-

This function or function block returns cached data.

See Program a Multi-Core Controller.

See Function Blocks - General Rules about how inputs and outputs work.

Output Bits

|

Hexadecimal |

Decimal |

Description |

|---|---|---|

|

0000H |

0 |

No Error |

|

0001H |

1 |

User-set E-stop via MC_EStop, E-stop |

|

0002H |

2 |

Loss of Feedback, E-stop |

|

0004H |

4 |

Drive Fault, E-stop |

|

0008H |

8 |

Drive Communication Failure, E-stop |

|

0400H |

1024 |

Synchronization Error, C-stop |

|

0700H |

7192 |

Drive Overtravel Limit Exceeded, Cstop. |

-

-

Multiple errors can be active at the same time.

Example: If a User-set E-stop and an Excess Position Error E-stop are both active, the value is 00000011H (17 decimal).

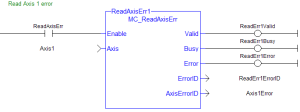

Figure 1: MC_ReadAxisErr

FBD Language Example

Not available.

FFLD Language Example

IL Language Example

Not available.

ST Language Example

(* MC_ReadAxisErr ST example *)

Inst_MC_ReadAxisErr( TRUE, Axis1 );

//Inst_MC_ReadAxisErr is an instance of MC_ReadAxisErr function block

AxisErrorBits := Inst_MC_ReadAxisErr.AxisErrorID; //AxisErrorID contains the error bits