AKT2G-SM-L15-000

Stepper motor terminal, 24 V DC, 1.5 A, vector control

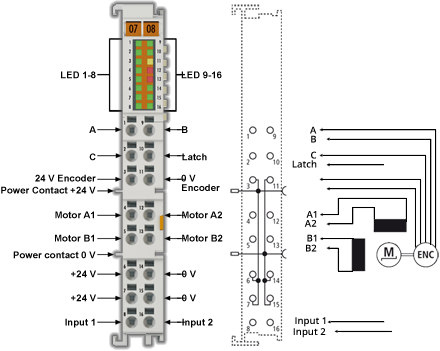

The AKT2G-SM-L15 EtherCAT![]() ***EtherCAT is an open, high-performance Ethernet-based fieldbus system. The development goal of EtherCAT was to apply Ethernet to automation applications which require short data update times (also called cycle times) with low communication jitter (for synchronization purposes) and low hardware costs Terminal is intended for stepper motors with low performance range. The PWM output stages cover a wide range of voltages and currents. Together with two inputs for limit switches, they are located in the EtherCAT Terminal.

***EtherCAT is an open, high-performance Ethernet-based fieldbus system. The development goal of EtherCAT was to apply Ethernet to automation applications which require short data update times (also called cycle times) with low communication jitter (for synchronization purposes) and low hardware costs Terminal is intended for stepper motors with low performance range. The PWM output stages cover a wide range of voltages and currents. Together with two inputs for limit switches, they are located in the EtherCAT Terminal.

The SM-L15 can be adjusted to the motor and the application by changing just a few parameters. These stepper motors can be operated with vector control. This control technique offers various benefits, such as better dynamics and lower power consumption. Together with a stepper motor and an encoder, the SM-L15 represents an inexpensive small servo axis.

The LEDs indicate status, warning and error messages as well as possibly active limitations.

Quick Links

- About Stepper Motors

- Standard Mode

- AKT2G-SM-Lx Object Description

- AKT2G-SM-Lxx PDO Assignment

- AKT2G-SM-Lxx Diagnostic Messages

- Mounting and Wiring of I/O Terminals

- AKT2G-SM-L15 LEDs & Connections

- AKT2G-SM-L15 General Connection Examples

Technical Data

| Technical Data | AKT2G-SM-L15 |

|---|---|

| Number of outputs | 1 stepper motor, 2 phases |

| Number of digital inputs | 2 limit position, 4 for an encoder system |

| Number of digital outputs | 1 configurable for brake (0.5 A) |

| Supply voltage | 24 V DC (-15%/+20%) |

| Motor Current/Phase (RMS) values without fan cartridge ZB8610 | 1.06 A |

| Motor Current/Phase (RMS) values with fan cartridge ZB8610 | 1.12 A |

| Maximum output current without fan cartridge ZB8610 | 1.5 A (overload- and short-circuit-proof) |

| Maximum output current with fan cartridge ZB8610 | 3.0 A (overload- and short-circuit-proof) |

| Operating modes |

|

| Maximum step frequency | 1000, 2000, 4000, 8000 or 16000 full steps/s (configurable) |

| Step pattern | up to 64-fold micro stepping (automatic switching, speed-dependent) |

| Current controller frequency | approx. 30 kHz |

| Encoder pulse frequency | maximum 400,000 increments/s (4-fold evaluation) |

| Input signal voltage "0" | -3 V … 2 V |

| Input signal voltage "1" | 3.7 V … 28 V |

| Input Current | typ. 5 mA |

| Diagnostics LED | Warning strand A and B, error strand A and B, power, enable |

| Resolution | approx. 5,000 positions in typical applications (per revolution) |

| Power Supply | via the E-bus, encoder/driver stage: via the power contacts, motor: via terminal contacts |

| Current consumption from the E-bus | typ. 100 mA |

| Electrical isolation | 500 V (E-bus/signal voltage) |

| Support NoCoEStorage | yes |

| Configuration | no address setting required |

| Weight | approx. 60 g |

| Permissible ambient temperature range during operation | 0°C ... +55°C |

| Permissible ambient temperature range during storage | -25°C ... + 85°C |

| Permissible relative humidity | 95%, no condensation |

| Dimensions (W x H x D) | approx. 27 mm x 100 mm x 70 mm (connected width: 24 mm) |

| Installation | on 35 mm mounting rail according to EN 60715 |

| Vibration / shock resistance | conforms to EN 60068-2-6/EN 60068-2-27 |

| EMC immunity/emission | according to EN 61000-6-2 / EN 61000-6-4 according to IEC |

| EMC category | Category C3 - standard Category C2, C1 - auxiliary filter required |

| Protection class | IP 20 |

| Installation position |

|

| Approval | CE cULus |