![]()

Function Block - Stop with the specified deceleration.

Function Block - Stop with the specified deceleration.

This does NOT remove the input source, but to stop the drive from continuing to move.

- This function stops any current Generator Motion.

- It causes the axis to start ignoring any changes in Pipe position to be added into the reference position.

- It decelerates, if moving, at a programmed rate.

Inputs

|

Input |

Data Type |

Range |

Unit |

Default |

Description |

|---|---|---|---|---|---|

|

ID |

DINT |

No range |

N/A |

No default |

ID Name of the Axis block. |

|

Start |

BOOL |

FALSE, TRUE |

N/A |

No default |

|

|

Deceleration |

LREAL |

No range |

User unit/sec2 |

No default |

|

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

Default (.Q) |

BOOL |

FALSE, TRUE |

N/A |

Becomes TRUE when the Axis is completely stopped.

|

|

GenPos |

LREAL |

|

User units |

Corresponds to the Generator Position input to the axis at the time the stop is triggered. See Axis Pipe Block about positions. |

|

PipePos |

LREAL |

|

User units |

Corresponds to the Pipe Position input to the axis at the time the stop is triggered. See Axis Pipe Block about positions. |

|

RealignPos |

LREAL |

|

User units |

Realign Position is the Reference Position at which the stop is triggered.

|

|

StopPos |

LREAL |

|

User units |

Corresponds to the last Reference Position sent to the drive at the time when the Axis is completely stopped.

|

Remarks

-

-

This function or function block returns cached data.

See Program a Multi-Core Controller.

- After stopping the drive, the motion must be restarted by realigning the Actual Position with the Reference Position.

- See Axis Pipe Block about positions.

- When the stop occurs, the master keeps moving and the axis starts ignoring the Pipe Position value and begins a controlled stop based on the input parameters.

See Axis Pipe Block for more information about Pipe Position.- At this point, any Axis Block level profile (issued from an FB like MLAxisAbs, MLAxisRel...) are aborted.

- When the stop is complete, it is up to the application to decide how to move the axis, master, or both to a position where they can be realigned, and the master restarted.

- The MLAxisReAlign function is used to move the axis to a restart position in order to enable synchronized machine motion to start again.

- Once the realign function is successfully completed, the Pipe Position is again summed with the Generator Position to create the Reference Position.

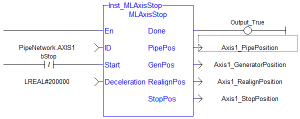

FBD Language Example

FFLD Language Example

IL Language Example

Not available.

ST Language Example

Inst_MLAxisStop(PipeNetwork.AXIS1, bStop, 200000);

If Inst_MLAxisStop.Done Then

Axis1_PipePosition := Inst_MLAxisStop.PipePos;

Axis1_GeneratorPosition := Inst_MLAxisStop.GenPos;

Axis1_RealignPosition := Inst_MLAxisStop.RealignPos;

Axis1_StopPosition := Inst_MLAxisStop.StopPos;

End_if;

See Also