SLS (Safely Limited Speed)

SLS description for drive option Functional Safety 3.

Description

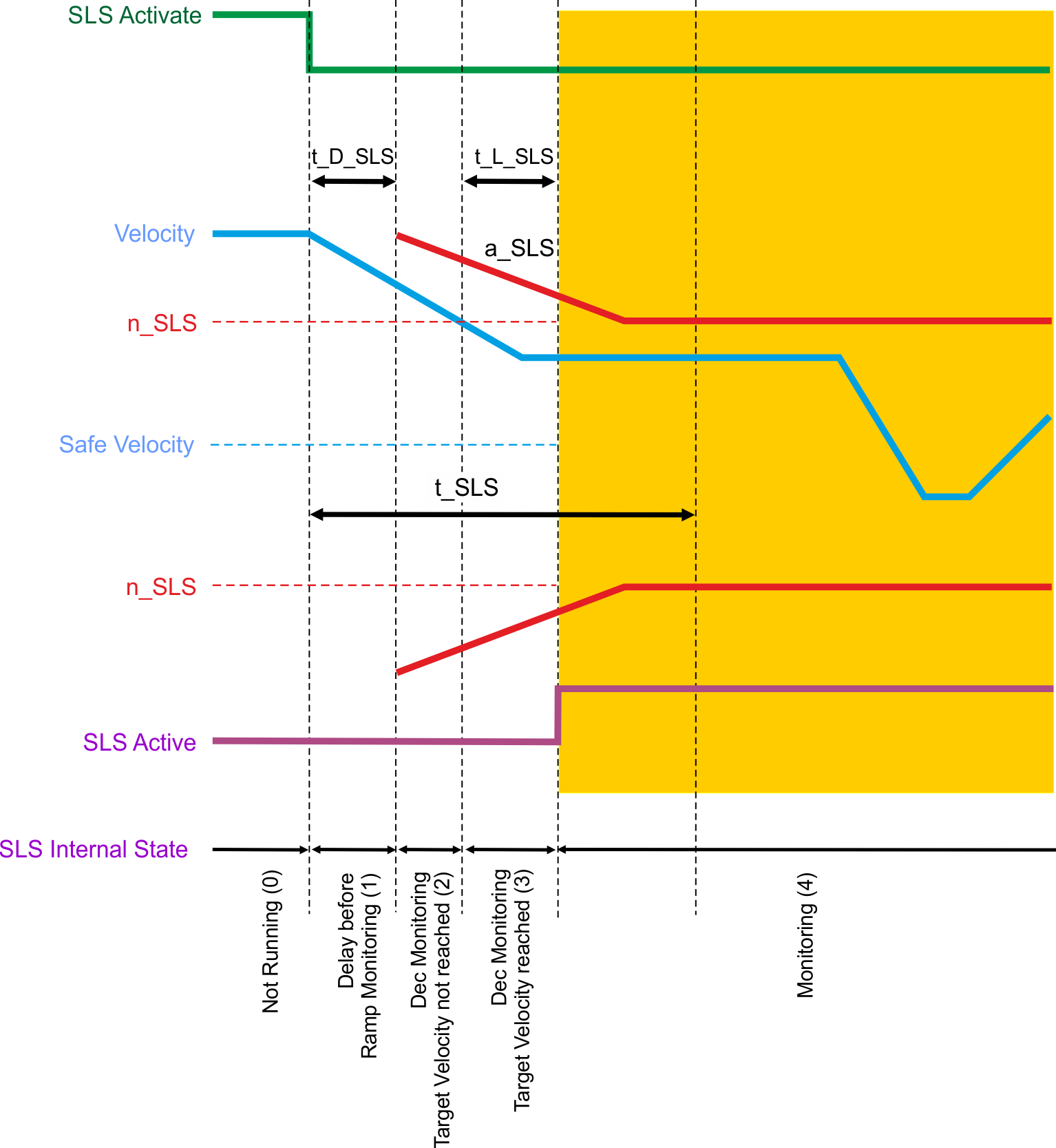

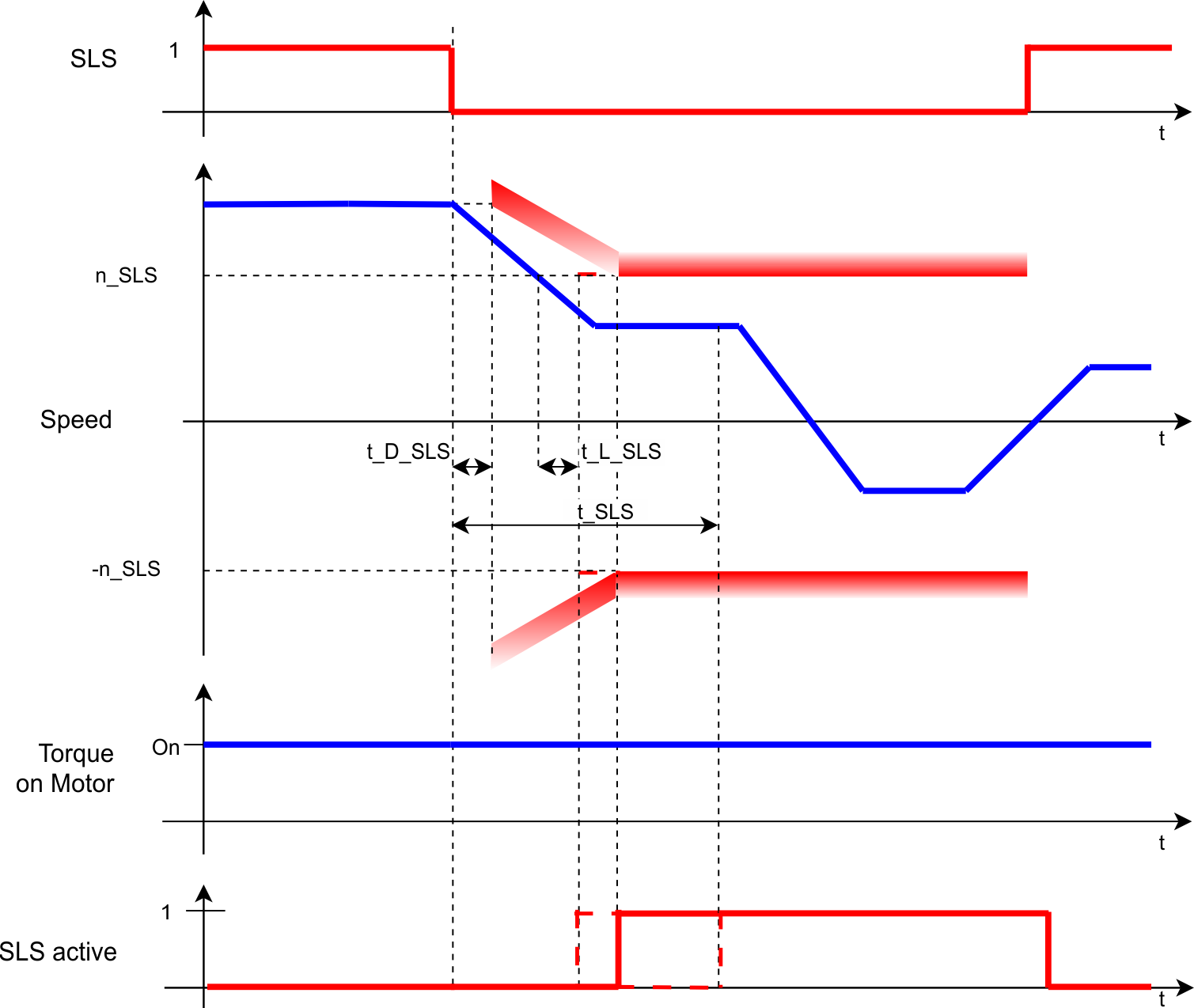

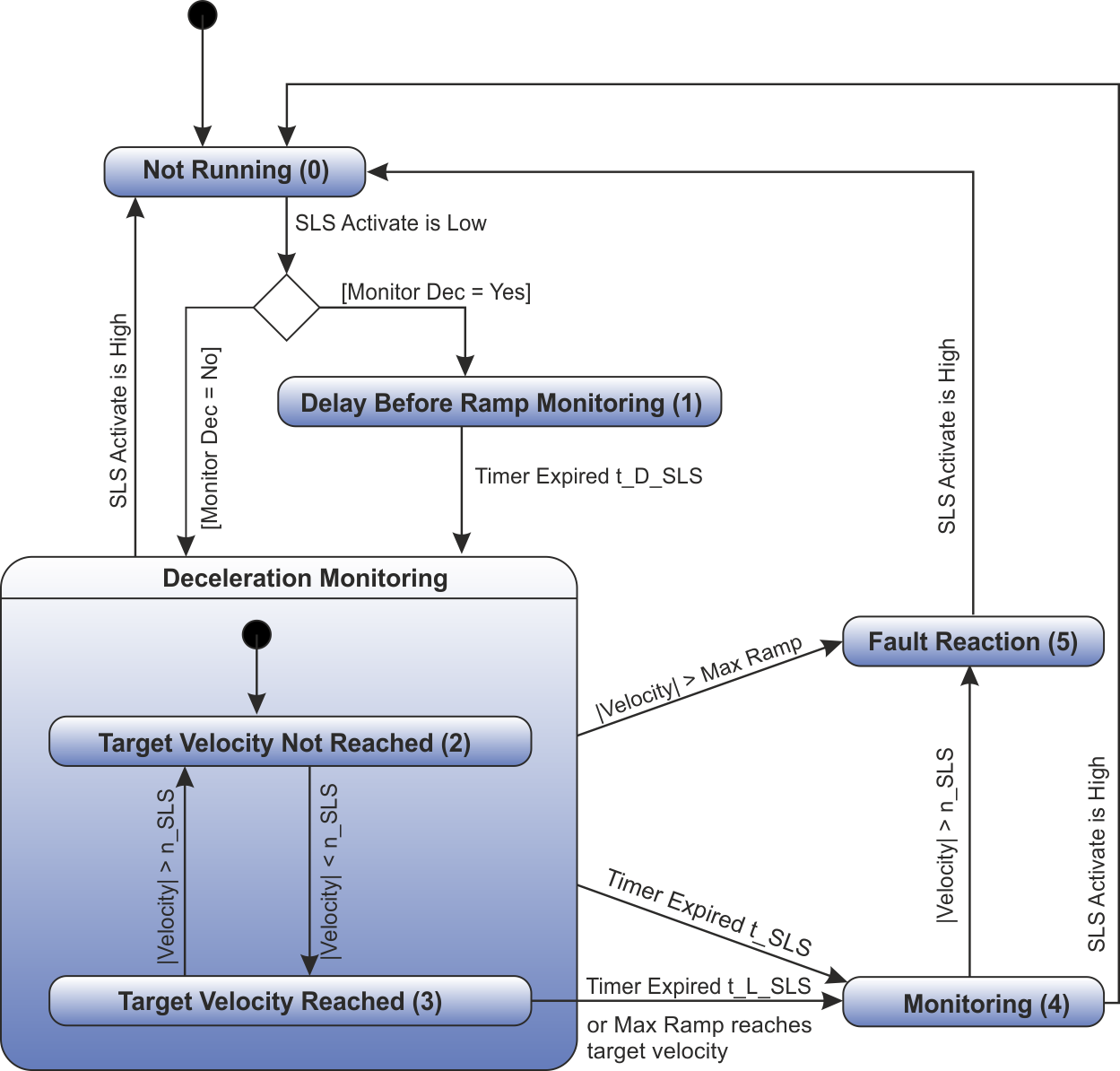

SLS, when activated, monitors the absolute velocity of the axis and ensures that it does not go above the configured limit. If it does, the function will activate a configurable fault reaction.

Once the activation request is received, SLS will become active, depending on whichever happens first:

- The time to velocity monitoring is elapsed (t_SLS).

- The minimum deceleration limit ramp hits the configured limit (n_SLS).

- The current velocity remains below the configured limit (n_SLS) for a given amount of time

(t_L_SLS) (only when deceleration monitoring configured). - Immediately, when the velocity is already below the configured limit (n_SLS) (only when deceleration monitoring not configured).

Optionally, the deceleration ramp could be monitored after some delay (t_D_SLS) checking that the actual velocity is below the computed velocity ramp (a_SLS). If the velocity is above the computed velocity ramp, SLS will activate the fault reaction.

Number of Instances

Three instances per axis.

Function Input / Output Variables

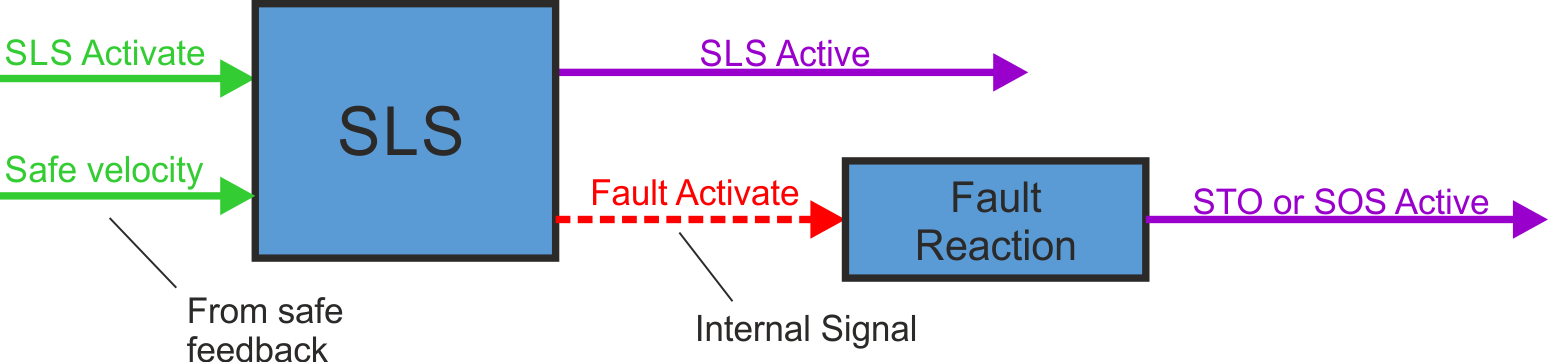

Inputs

- SLS Activate can be triggered by FSoE or safe digital inputs (must be mapped)

- Safe velocity: velocity signal from safe feedback

Outputs

- SLS Active: logical status of the SLS function

- Fault Activate: activate fault reaction

Activation

|

Activation by FSoE |

|

|

Activation by safe digital inputs |

|

Timing

Related Parameters

Safety parameters

| Name |

Variables |

Default |

Parameter |

|---|---|---|---|

|

Function Activation |

- |

0 (Never active) |

|

|

Safe Input |

- |

0 (Not used) |

|

|

FSOE |

- |

0 (Not used) |

|

|

Time to Velocity Monitoring |

t_SLS |

2 ms |

|

|

Velocity Limit |

n_SLS |

1 (Vel user units) |

|

|

Time for Velocity in Limits |

t_L_SLS |

1 ms |

|

|

Deceleration Monitoring |

- |

0 (Disabled) |

|

|

Deceleration Limit |

a_SLS |

0 (Dec user units) |

|

|

Time Delay Deceleration Monitoring |

t_D_SLS |

1 ms |

|

|

Fault Reaction |

- |

1 (STO) |

Diagnostic parameters

| Name |

Variables |

Default |

Parameter |

|---|---|---|---|

|

Function Active Status |

- |

- |

|

|

Function Internal Status |

- |

- |

State Diagram

SLS is active if the internal state is "Monitoring (4)" or "Fault reaction (5)".

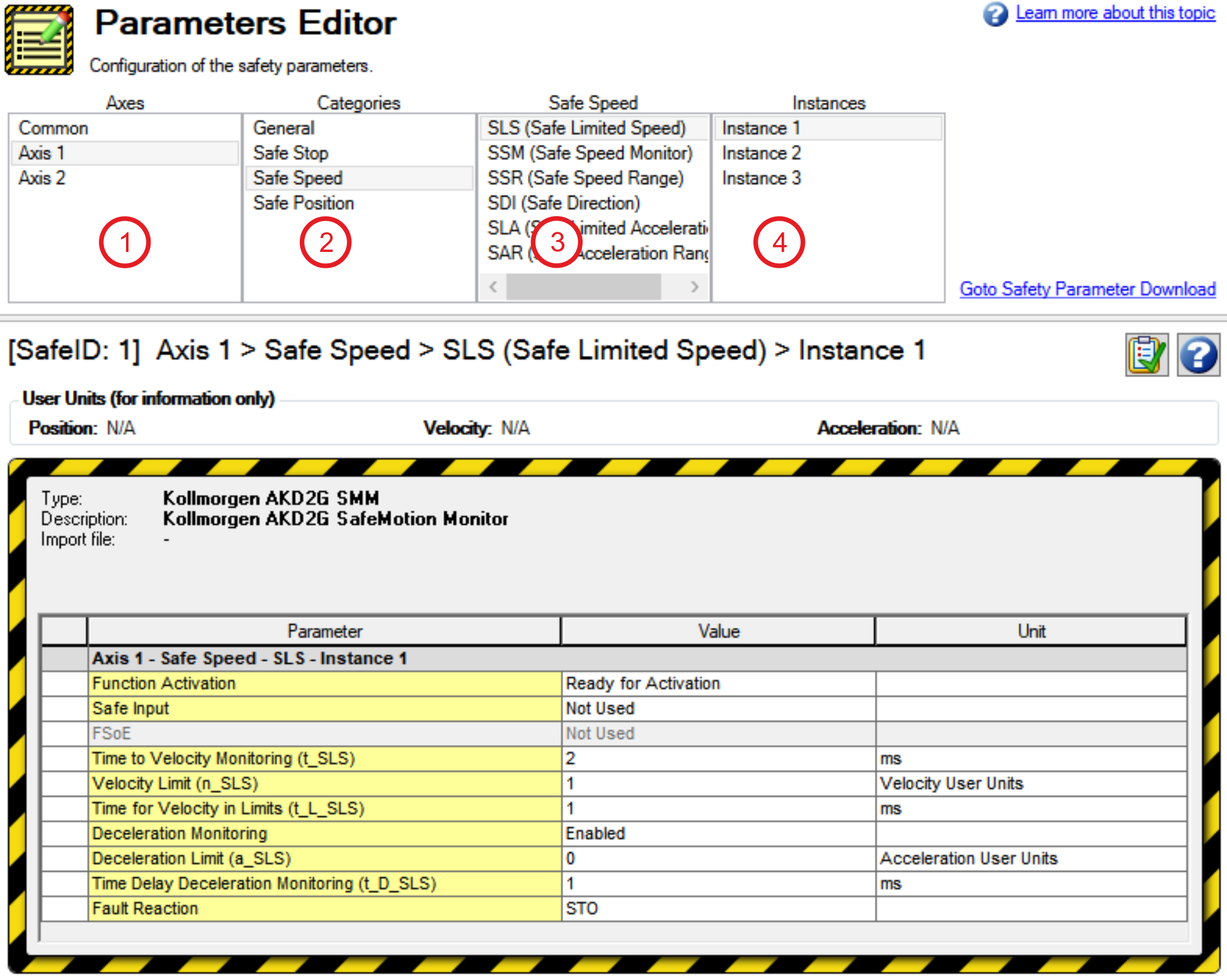

Setup in WorkBench

Select the drive and open the Safety Parameterization view (see "Parameters Editor").

Choose the axis (1), category (2), SLS function (3) and the instance number (4).

Fault Reaction / Failure Messages

SLS has a configurable fault reaction. STO is used by default but can be replaced by SS1 Instance 1 or SS2 Instance 1. When the fault reaction is activated, SLS remains active and the internal state (AXIS#.SAFE.SLS_#.INTERNALSTATE) is set to failed state (5).

Safety State / Status Signals

The signal AXIS#.SAFE.SLS_#.ACTIVE can be monitored by safe digital outputs with OSSD pulses (see "OSSD"). The status signal must be mapped to the safe digital output. Two outputs can be combined to a dual channel output. For parameter description refer to Functional Safety Parameter Reference.

Safety Properties

Refer to (➜ # 1, Safety Properties Overview).