![]()

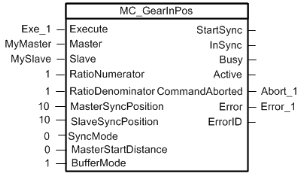

Function Block - Performs a slave axis move which follows the master axis based on the ratio specified by RatioNumerator and RatioDenominator.

Function Block - Performs a slave axis move which follows the master axis based on the ratio specified by RatioNumerator and RatioDenominator.

Inputs

|

Input |

Data Type |

Range |

Unit |

Default |

Description |

|---|---|---|---|---|---|

|

Execute |

BOOL |

0, 1 |

N/A |

No default |

On the rising edge, request to queue the slave gear ratio move. |

|

Master |

AXIS_REF |

1 to 256 |

N/A |

No default |

Name of a declared instance of the AXIS_REF library function.

|

|

Slave |

AXIS_REF |

1 to 256 |

N/A |

No default |

AXIS_REF.AXIS_NUM is the slave axis number. See AXIS_REF Structure. |

|

RatioNumerator |

DINT |

-2147483648 to 2147483647 |

N/A |

No default |

Numerator of master/slave ratio. The + or - sign indicates the direction for the slave axis. |

|

RatioDenominator |

DINT |

-2147483648 to 2147483647 |

N/A |

No default |

Denominator of master/slave ratio.

|

|

MasterSyncPosition |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Master axis sync position. 14 to 15 significant digits of accuracy. |

|

SlaveSyncPosition |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Slave axis sync position. 14 to 15 significant digits of accuracy. |

|

SyncMode |

INT |

0, 1 |

N/A |

No default |

SyncMode determines the allowed conditions for synchronization.

|

|

MasterStartDistance |

LREAL |

-1.7E308 to 1.7E308 |

User units |

No default |

When the master axis reaches this distance before MasterSyncPosition, the slave axis begins its lock-on process.

|

|

BufferMode |

SINT |

1 |

N/A |

No default |

|

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

StartSync |

BOOL |

No range |

N/A |

Indicates the master axis has reached the MasterStartDistance from the MasterSyncPosition and the lock-on process has begun. |

|

InSync |

BOOL |

No range |

N/A |

Indicated the slave axis is locked on to the master axis. |

|

Busy |

BOOL |

No range |

N/A |

High from the moment the Execute input goes high until the time the move is ended. |

|

Active |

BOOL |

No range |

N/A |

Indicates this move is the Active move. |

|

CommandAborted |

BOOL |

No range |

N/A |

Indicates the move was aborted. If the abort arises because the inputs cause inconsistent motion, then this FB:

|

|

Error |

BOOL |

No range |

N/A |

Indicates either:

|

|

ErrorID |

INT |

No range |

N/A |

Indicates the error if the Error output is set to TRUE. |

Remarks

SlaveCommandPosition = MasterActualPosition * RatioNumerator / RatioDenominator

-

- This function block starts a motion-related action and stores data for calculations and error checking.

If using a dual-core controller, see Call Function Blocks Multiple Times in the Same Cycle.

- See Function Blocks - General Rules about how inputs and outputs work.

- This function block allows the application to specify sync positions for the master and slave axes.

- It is the point in which the master and slave axes become engaged in synchronous motion.

- When the master axis reaches the MasterStartDistance from the MasterSyncPosition, the slave axis begins to accelerate to the target velocity determined by the master axis velocity and the ratio.

- The slave axis arrives at the target velocity and the SlaveSyncPosition at the same time the master axis arrives at the MasterSyncPosition.

- At that time, the slave is locked on to the master and follows the master at the ratio specified.

- The slave axis continues to follow the master axis until this move is aborted.

Aborting Gearing

Gearing functions can generate large accelerations while following the master.

- If the aborting function block has small, non-zero Jerk, or small acceleration values, it can take a long time for an accelerating axis to reach the target velocity, or position of the aborting function block.

- If the Jerk and/or acceleration of the aborting function cannot be increased to suitable values, it may be desirable to either:

- Abort the gearing function with an MC_GearOut with higher accelerations and/or Jerk values (or zero jerk value).

- Execute the next MC motion function block (e.g., MC_Halt).

- If the Jerk and/or acceleration of the aborting function cannot be increased to suitable values, it may be desirable to either:

Time to Reach the Target Velocity

While following the master, gearing functions can generate large accelerations.

- If the gearing function is aborted while the axis is currently accelerating, and the aborting function block has small non-zero Jerk or small acceleration values, it can take a long time to reach the target velocity, or position of the aborting function block.

- If the Jerk and/or acceleration of the aborting function cannot be increased to suitable values, it may be desirable to either:

- Abort the gearing function with an MC_GearOut with higher accelerations and/or Jerk values (or zero jerk value).

- Execute the next MC motion function block (e.g., MC_Halt).

- If the Jerk and/or acceleration of the aborting function cannot be increased to suitable values, it may be desirable to either:

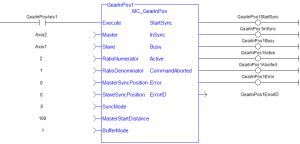

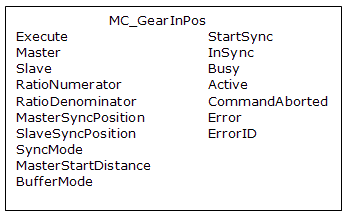

Figure 1: MC_GearInPos

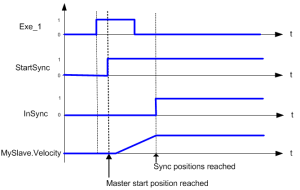

Time Diagram

Figure 2: Time Diagram

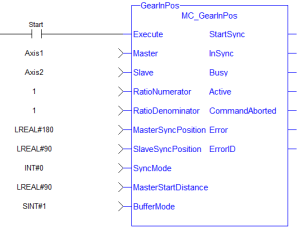

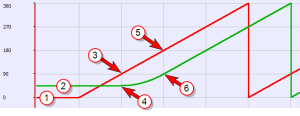

Example

- Master and Slave are rotary axes with rollovers at 360 degrees.

- The Master initial position is 0 degrees and the slave initial position is 45 degrees.

- The GearInPos FB commands the slave to accelerate up to the geared ratio (1:1) during the master start distance (90 degrees) and be synchronized with the master at the master and slave sync positions.

|

FBD Language Example

Not available.

FFLD Language Example

IL Language Example

Not available.

ST Language Example

(* MC_GearInPos ST example *)

Inst_MC_GearInPos( GearInPosReq, Axis1, Axis2, 2, 1, 0, 0, 0, 100.0, 1 );

//Inst_MC_GearInPos is instance of MC_GearInPos

GearInPosSync:= Inst_MC_GearInPos.InSync;

//store InSync output into user defined variable