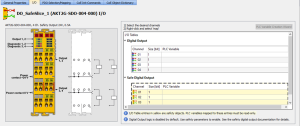

Map I/O from the Project Explorer

-

- For information on mapping I/O with third-party devices, see the PDO Selection/Mapping tab.

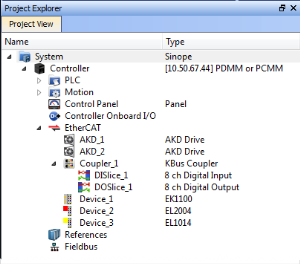

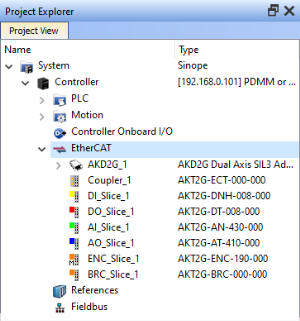

- In the Project Explorer, expand the Controller node and the EtherCAT nodes to access your devices.

- Accessing the device properties is slightly different depending upon the device.

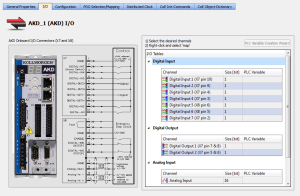

- AKD or AKD2G

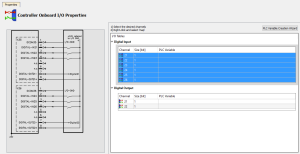

- Controller

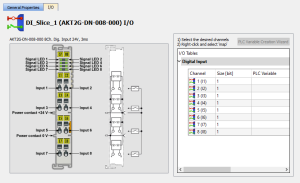

- I/O Slice

- Safety Slices

- There are several ways to map variables:

- Drag and drop a variable from the Dictionary onto a table entry.

- Use the PLC Variable Creation Wizard for Kollmorgen devices.

- Directly map/unmap the Inputs/Outputs to PLC variables using the PLC Variable Selector.

-

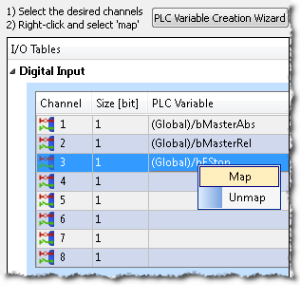

- The Unmap command in the contextual menu is used to remove the link between the variable and the associated channel(s).

In addition, deleting a variable from the dictionary which is mapped to the channel(s) also removes the link(s). The list of variables is filtered to display only those with relevant types.

- PLC Variable Selector displays Read Only variables when mapping the Input channels from the I/O tab.

- Variables assigned to the Safe Digital Input and Safe Digital Output channels must be Read Only.

|

|

| AKT (K-Bus) devices | AKT2G (E-Bus) devices |

For I/O slices, double-click the I/O Slice under EtherCAT (AKT2G) or the Coupler entry (AKT) in the project tree. Then click the I/O tab.

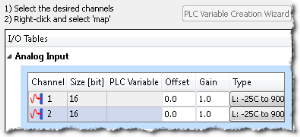

For Slice Analog I/O and thermocouples, the offset and gain parameters must be defined.

For safety devices, double-click the Safety I/O Slice under EtherCAT in the project tree and click the I/O tab.

Digital output logic on the safety slices / devices is typically disabled by default from the standard PLC.

See the Description of Safety Parameters and the AKT2G-SDO-004-000 Safety Terminal with Four Digital Fail-safe Outputs table for details.

Select the channel(s) to map. Selection may be done by click-dragging or shift-clicking a range of entries. The entire table may be selected by clicking on its border.

After the selection is made, right-click and select Map or press the Enter key.

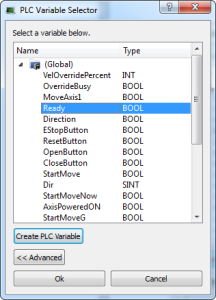

This opens the PLC Variable Selector.

Choose the variable to be linked to the channel(s) or PDO object.

-

-

The limitations of PLC variable mapping are:

- Each PLC variable can be mapped to an EtherCAT I/O and exclusively to either:

- a Controller Onboard I/O.

- an external driver.

- Because a variable can only be mapped to one channel or PDO object, when you link a variable to a new channel or PDO object, the previous mapping is removed (even if linked to another slice or device).

- Individual bits within a variable can be mapped to multiple I/O channels on different devices (AKD, AKD PDMM, PCMM, or Slice).

Example: The same PLC variable cannot be mapped to both Profinet and a Controller Onboard I/O but it is possible with a regular EtherCAT I/O.

- Each PLC variable can be mapped to an EtherCAT I/O and exclusively to either:

When a device is removed using ECATDeviceAction:

- Variable mapped to an Analog or Digital Input Type

- The value of the variable becomes '0' when the mapped device is removed.

- The device I/O value is automatically reconnected to the variable when the device is reconnected to the network.

- Variable mapped to an Analog or Digital Output

- The value is not sent to the device when the mapped device is removed.

- When the device is reconnected, the value is sent to the I/O automatically.

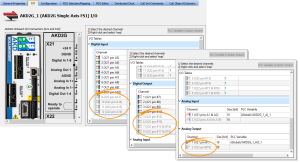

All of the I/Os mapped to the X22 connector are grayed out in the IO tab:

-

-

AKD2G drives are available with various I/O options.

An AKD2G drive of one variant can be replaced in the KAS project with a drive that has a different I/O option.

See the AKD2G Model Nomenclature section in Automation and Motion Control Programmable Automation Solutions for available models and I/O options.

See Also:

- PLC Variable Selector for information about the Create PLC Variable and Advanced buttons.

- Analog I/O Parameters for information about parameters.

- Configure Onboard I/O for information about the AKD Onboard EtherCAT I/Os.

- Controller Onboard I/O for information about the AKD PDMM or PCMM local digital I/Os.