![]()

Function Block - Facilitates dancer and tension control in an electronic geared master/slave machine design.

Function Block - Facilitates dancer and tension control in an electronic geared master/slave machine design.

Inputs

|

Input |

Data Type |

Range |

Unit |

Default |

Description |

|---|---|---|---|---|---|

|

Enable |

BOOL |

0 to 1 |

N/A |

No default |

Enables execution. |

|

MasterID |

AXIS_REF |

N/A |

N/A |

No default |

Master axis identifier. |

|

SlaveID |

AXIS_REF |

N/A |

N/A |

No default |

Slave axis identifier. |

|

RatioNumerator |

DINT |

-2147483648 to 2147483647 |

N/A |

No default |

Numerator of master/slave ratio. |

|

RatioDenominator |

DINT |

-2147483648 to 2147483647 |

N/A |

No default |

Denominator of master/slave ratio. |

|

Acceleration |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Trapezoidal: Acceleration rate.

|

|

Deceleration |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Trapezoidal: Deceleration rate.

|

|

Jerk |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Trapezoidal: 0 (zero).

|

|

Kp |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Proportional gain. 14 to 15 significant digits of accuracy. |

|

Ti |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Integral gain. 14 to 15 significant digits of accuracy. |

|

Td |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Derivative gain. 14 to 15 significant digits of accuracy. |

|

DeviceFBValue |

DINT |

-2147483648 to 2147483647 |

N/A |

No default |

Analog input. |

|

DeviceSetPoint |

DINT |

-2147483648 to 2147483647 |

N/A |

No default |

Analog set point. |

|

ErrorDB |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Maximum or minimum error between DeviceFBValue and DeviceSetPoint before a change takes place. 14 to 15 significant digits of accuracy. |

|

RatioLimitPercent |

LREAL |

-1.7E308 to 1.7E308 |

N/A |

No default |

Maximum and minimum master/slave ratio window. 14 to 15 significant digits of accuracy. |

|

ErrorCalcMode |

BOOL |

0 to 1 |

N/A |

No default |

|

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

OK |

BOOL |

0 to 1 |

N/A |

The output has power flow after the enable input has been energized. |

|

NewRatio |

REAL |

-3.4E38 to 3.4E38 |

N/A |

New master/slave ratio. 6 to 7 significant digits of accuracy. |

|

Error |

BOOL |

0 to 1 |

N/A |

Function block error. |

|

ErrorID |

INT |

-32768 to +32767 |

N/A |

Function block error value. |

Remarks

- This facilitation is done by using the analog feedback from an LVDT, tension transducer, potentiometer, encoder, resolver or some other similar device.

- The analog feedback value is compared to a pre-determined analog set-point.

- The difference or error is used in a PID algorithm with the summed output driving changes to the master/slave gearing relationship.

- This results in the slave axis either speeding up or slowing down to maintain desired tension.

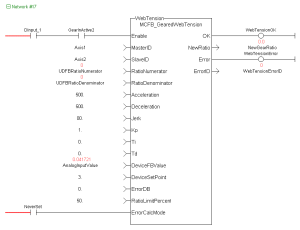

This image shows the function or function block I/O.

Figure 1: MCFB_GearedWebTension

Usage

- This UDFB is used in conjunction with the main ladder MC_GearIn function.

- It is assumed that the master/slave move is active.

- Internal to the UDFB is another call to the MC_GearIn function.

- Therefore, the MasterID, SlaveID, RatioNumerator, RatioDenominator, Acceleration, Deceleration, and Jerk inputs are the same values as the main ladder MC_GearIn function input values, both with the Buffer input of 0 (zero).

- This assures that the initial starting master/slave ratio will transition to the new Kollmorgen UDFB ratio smoothly.

- This UDFB changes the master/slave ratio defined by the MC_GearIn function based on the error between the analog input and the analog set-point.

- The magnitude of the ratio and the rate of the ratio change is defined by the Kp, Ti, Td PID gain values.

- The new ratio calculated is output at the NewRatio output.

- The RatioLimitPercent input is the maximum and minimum theoretical new ratio that can be changed.

- This provides a +/- window limit around the running ratio to prevent unwanted motion in the event of a web break or analog feedback failure.

Example 1

-

-

This example assumes the analog feedback device is located after (or downstream in the process) the feedroll axis.

RatioNumerator = 1

RatioDenominator = 2 Therefore the master/slave starting ratio is 0.5000000

ErrorCaclMode = 0

DeviceFBValue = 6

DeviceSetPoint = 4 Therefore error 6 – 4 = 2

Kp = 0.005

Ti = 0

Td= 0

From the equation:

New RatioDenominator = (RatioDenominator - Kp * error)

- The new RatioDenominator = (2 - 0.005*2) = 1.99.

- The new master/slave running ratio is 1 / 1.99 = 0.502512562.

- Since the master/slave ratio is greater than the previous ratio, the slave axis is going faster and the tension is reduced.

Example 2

-

-

This example assumes the analog feedback device is located before (or upstream in the process) the feedroll axis.

RatioNumerator = 1

RatioDenominator = 2 Therefore the master/slave starting ratio is 0.5000000

ErrorCaclMode = 1

DeviceFBValue = 6

DeviceSetPoint = 4 Therefore error is 4 – 6 = -2

Kp = 0.005

Ti = 0

Td= 0

From the equation:

New RatioDenominator = (RatioDenominator – (Kp * error))

- The new RatioDenominator = (2 + 0.005*2) = 2.01.

- The new master/slave running ratio is 1 / 2.01 = 0.497512437.

- Since the master/slave ratio is less than the previous ratio, the slave axis is going slower and the tension is reduced.

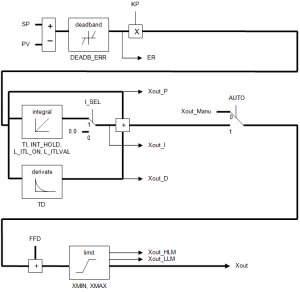

PID Function in KAS

There is a PID function in KAS that could be used for the PID control section in the UDFB.

Figure 2: PID Function

Programming Tips

- The FB_FirstOrderDigitalFilter UDFB can be used to decrease excess dither on the analog input.

- The filtered analog value is then used at the DeviceFBValue input of the MCFB_GearedWebTension UDFB.

- The assumption is an MC_GearIn function block is first called in the main ladder and these initial values are used at the inputs for the UDFB.

- The resolution of the initial MC_GearIn the RatioNumerator and RatioDenominator inputs are directly related to the resolution of the calculated master/slave ratio (from the UDFB inputs) and may need to be scaled accordingly.

Example 1

- No scaling

Initial MC_GearIn input RatioNumerator = 2.

Initial MC_GearIn input RatioDenominator = 1 then initial Master/Slave ratio = 2. - UDFB input RatioNumerator = 2.

UDFB input RatioDenominator = 1 then UDFB Master/Slave ratio = 2. - UDFB input DeviceFBValue = 4.

UDFB input DeviceFBSetpoint = 3 then Device PID error = 1 assume KP = 1, Ti and Td =0. - New UDFB RatioNumerator = Current RatioNumerator – PID error = 2 – 1 = 1 then new UDFB Master/Slave ratio = 1.

Resolution = Master/Slave ratio:PID Error ratio = 1:1.

- The resolution is so coarse that a change of 1 for the error output of the PID creates a Master/Slave ratio change of 1.

- This result is a significant change to the slave velocity that will probably cause excess slack or web breakage.

Example 2

- Scaling value = 1000

Initial MC_GearIn input RatioNumerator = 2.

Initial MC_GearIn input RatioDenominator = 1 then initial Master/Slave ratio = 2. - UDFB input RatioNumerator = 2000

UDFB input RatioDenominator = 1000 then UDFB Master/Slave ratio = 2. - UDFB input DeviceFBValue = 4.

UDFB input DeviceFBSetpoint = 3 then Device PID error = 1 assume KP = 1, Ti and Td =0. - New UDFB RatioNumerator = Current RatioNumerator – PID error = 2000– 1 =1999 then new UDFB Master/Slave ratio = 1999.

Resolution = Master/Slave ratio: PID Error ratio = 2000:1.

- This resolution is much finer than Example 1.

- For a change of 1 for the error output of the PID this creates a Master/Slave ratio change of 1999.

- This results is a slower rate of change to the slave velocity that is more suited to good tension in a machine process.

FBD Language Example

FFLD Language Example

IL Language Example

Not available.

ST Language Example

Inst_MCFB_GearedWebTension( DInput_1, Axis1, Axis2,

ratioNumerator, ratioDenominator, 500.0, 500.0, 0.0, 1.0, 0.0, 0.0,

AnalogInputValue, 3.0, 0.0, 50.0, NeverSet); WebTensionOK := Inst_MCFB_GearedWebTension.OK; NewGearRatio := Inst_MCFB_GearedWebTension.NewRatio; WebTensionHasError := Inst_MCFB_GearedWebTension.Error; WebTensionErrorID := Inst_MCFB_GearedWebTension.ErrorID;

See Also