![]()

Function Block- Enables Mark-to-Machine registration.

Function Block- Enables Mark-to-Machine registration.

Inputs

|

Input |

Data Type |

Range |

Unit |

Default |

Description |

|---|---|---|---|---|---|

|

En |

BOOL |

FALSE, TRUE |

N/A |

No default |

On the rising edge, request to enable registration. |

|

Axis |

AXIS_REF |

The range of .AXIS_NUM is [1, 256] |

N/A |

N/A |

Axis whose position is used to determine a good mark. |

|

TriggerInput |

TRIGGER_REF |

No range |

N/A |

No default |

Structure specifying the fast input. The structure elements are: DirectionINT Range = 1, 5.

InputID INT Range = 0 to 1

TrigIDINT Range = 0 to 256.

|

|

Distance |

LREAL |

|

User units |

N/A |

|

|

Tolerance |

LREAL |

When converted to feedback units, |

User units |

N/A |

This value specifies the distance, plus or minus, about Distance to determine if the mark detected by the fast input is a good mark. |

|

Ignore |

LREAL |

|

User units |

N/A |

This value specifies the distance after the previous good mark in which any detected marks are ignored. |

|

Target |

LREAL |

When converted to feedback units,

|

User units |

N/A |

|

|

Position |

LREAL |

When converted to feedback units,

|

User units |

N/A |

|

|

PosAxis |

AXIS_REF |

The range of .AXIS_NUM is [1, 256] |

N/A |

N/A |

The position of this axis at the time the fast input occurs is compared to the Target position. This comparison determines the amount of registration compensation to apply. |

|

CompAxis |

AXIS_REF |

The range of .AXIS_NUM is [1, 256] |

N/A |

N/A |

The calculated registration compensation is applied to this axis. |

|

PosTolerance |

LREAL |

When converted to feedback units, the range is [-251, 251-1]. |

User units |

N/A |

This value specifies the distance, plus or minus, about the Target position to determine if the position is accepted and the compensation value is calculated and applied. |

|

RatioNumerator |

DINT |

When converted to feedback units, |

User units |

N/A |

|

|

RatioDenominator |

DINT |

When converted to feedback units, |

User units |

N/A |

|

|

Options |

UINT |

See the MC_MachRegist Options Table. |

N/A |

N/A |

|

Outputs

|

Output |

Data Type |

Range |

Unit |

Description |

|---|---|---|---|---|

|

RegistOn |

BOOL |

FALSE, TRUE |

N/A |

Indicates registration is activated. |

|

Aborted |

BOOL |

FALSE, TRUE |

N/A |

Indicates registration has been terminated by MC_StopRegist. |

|

Error |

BOOL |

FALSE, TRUE |

N/A |

Indicates an invalid input was specified or the registration was terminated due to an error. |

|

ErrorID |

INT |

No range |

N/A |

|

Remarks

-

- This function block starts a motion-related action and stores data for calculations and error checking.

If using a dual-core controller, see Call Function Blocks Multiple Times in the Same Cycle.

-

- Is this the right function block to use?

See Decide which Function Blocks to Use for Registration and Registration Application Guide.

- It is used on any servo or digitizing axis and with any move type.

- It is used most frequently in master/slave applications.

|

Used with ... |

Effect |

|---|---|

|

Non-slave moves |

Resets the axis position when a good mark is captured by the fast input. |

|

Slave moves |

Applies a compensation offset to correct for the difference between the target position and the measured position. This provides the ability to compensate for product or process inconsistencies, provides a system that remains synchronized with no accumulated error, and maintains repeatable accuracy throughout the process. |

Transition and Registration

- A positive transition of the En input starts registration.

- The application may change the registration parameters while registration is active by changing the input values and causing another positive transition of the En input.

- The function block then reads and applies the new values.

- The axis number at the Axis input indicates the axis whose position, at the fast input, is used to determine if the mark is a good mark.

Distance, Tolerance, Ignore, Target Inputs

- The Distance, Tolerance, and Ignore inputs are used to determine whether or not the registration mark is good.

- For a mark to be recognized as good, it must be outside of the Ignore distance and the correct Distance from the previous mark +/- the Tolerance window.

- A mark is bad if it occurs outside of the “good tolerance band” and is not ignored.

- Both good marks and bad marks are recognized as marks, ignored marks are not recognized.

- If all marks are to be recognized as good marks, enter 0 (zero) at both Distance and Tolerance.

- The Distance value defines the distance between good marks.

- In Clear Lane and Product registration the Distance input value is typically the same as the Target input value.

- In Print registration, the Distance is typically not the same as Target.

- The Tolerance value is the distance, plus and minus, about Distance.

- Marks detected in this window are good marks and registration occurs.

- Marks detected outside this window and outside the Ignore band, are bad marks and registration does not occur.

- This window should be large enough to allow for the worst case error in the distance between the previous mark and the current mark.

- The Ignore value defines the distance from the previous mark where all marks detected by the fast input are ignored.

- This is crucial when registering products that do not have Clear Lane registration marks.

- The Target input is the expected target position that is used to calculate how much registration compensation is to be applied when a registration mark is considered good.

- When a good mark is detected, the position of the PosAxis is compared to the Target position to calculate a correction.

- The registration correction is only applied with master/slave move types.

Position and Option Inputs

- The Position input is the position value the registration Axis position is reset to when a good registration mark is detected.

- When a good mark occurs, the position of the PosAxis is compared to the Target position.

- This comparison is used to calculate the amount of registration compensation to apply to the CompAxis.

- Registration compensation is applied to the axis specified at the CompAxis input under these conditions:

- If CompAxis is a master axis, the compensation is applied to the master offsets of all its slaves.

- This shifts the master’s position as seen by its slaves.

- If CompAxis is executing a slave move (e.g., MC_GearIn or MC_CamIn), the compensation is applied directly to the axis.

- This comparison is used to calculate the amount of registration compensation to apply to the CompAxis.

- The PosTolerance input is the distance, plus and minus, about the Target position used to determine if compensation is applied.

- When a good mark occurs, the position of the PosAxis axis is checked to see if it lies in the window defined by PosTolerance.

- If it is in the window, compensation is applied.

- If it is outside the window, compensation is not applied even though a good mark was found.

- When a good mark occurs, the position of the PosAxis axis is checked to see if it lies in the window defined by PosTolerance.

- If PosAxis and CompAxis are different axes, the RatioNumerator and RatioDenominator inputs define the conversion factor for calculating the compensation value.

- This is needed because the amount of error between actual and target positions is determined by the PosAxis's position and the compensation is applied to the CompAxis.

- The RatioNumerator should typically be the number of User Units of CompAxis motion for one registration cycle.

- The RatioDenominator should typically be the number of User Units of PosAxis motion for one registration cycle.

- If PosAxis and CompAxis are the same, RatioNumerator and RatioDenominator should be the same value, thus resulting in a 1:1 ratio.

- When a good mark occurs, the position of the PosAxis is compared to the Target position.

- The Option input defines various modes of operation for registration.

- The first bit, 0001H, selects Absolute or Resetting.

- This refers to the way the second mark and all subsequent marks are determined to be good marks.

- With both registration schemes, the very first detected mark is the starting point.

- With Resetting registration, when the next mark is detected, the position of that mark becomes the starting point for the next good mark detection calculation and so on.

- The starting point is reset with each good or bad mark.

- This allows the product to re-synchronize, if necessary, due to process issues (e.g., product shift) etc.

- Absolute registration determines all good marks based on the very first mark.

- The position of the second and each subsequent mark is compared to an integer multiple of Distance from the very first mark.

- This method insures the product always registers to a known fixed distance.

- The starting point is reset with each good or bad mark.

- The third bit, 0004H, must be 0 (zero).

- Mark-to-machine registration requires time-based capture.

- The first bit, 0001H, selects Absolute or Resetting.

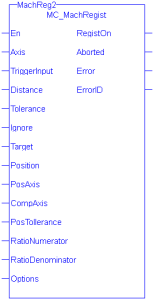

Figure 1: MC_MachRegist

MC_MachRegist Options Table

|

Hexadecimal |

Decimal |

Option |

Description |

|---|---|---|---|

|

0001 H |

1 |

Absolute/Resetting |

0 = Resetting, 1 = Absolute |

|

0002 H |

2 |

Reserved |

0 |

|

0004 H |

4 |

Time/position based capture |

0 = time based capture, 1 = position based capture |

|

0008 H |

8 |

Inhibit Reference on Good Mark |

0 = Perform reference, 1 = inhibit reference When this bit is set, the Position function block argument is unused and the axis position is not changed when a registration mark is encountered. |

|

0010H |

16 |

Inhibit Master Compensation |

0 = Perform Master Compensation, 1 = Inhibit Master Compensation |

|

0020H |

32 |

Inhibit Slave Compensation |

0 = Perform Slave Compensation, 1 = Inhibit Slave Compensation. |

-

-

To use Capture Engine 1, modify the input PDOs that are used and add the Latch Position 1 parameter.

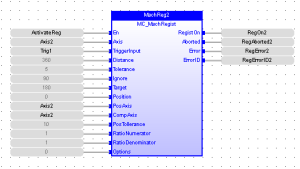

FBD Language Example

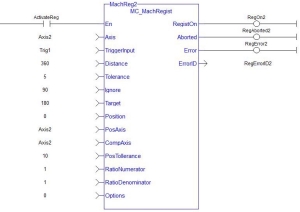

FFLD Language Example

IL Language Example

Not available.

ST Language Example

Inst_MC_MachRegist( ActivateReg, Axist2, Trig1, 360, 5, 90, 180, 0, Axis2, Axis2, 10, 1, 1, 0 );

See Also