FAQs

Basic

The Autorun feature may be deactivated.

- Open an Explorer window to see the autorun.exe file.

- Use the Run command in the contextual menu to manually start the installer.

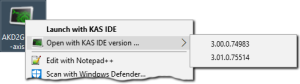

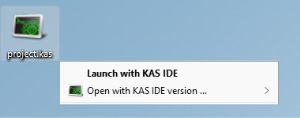

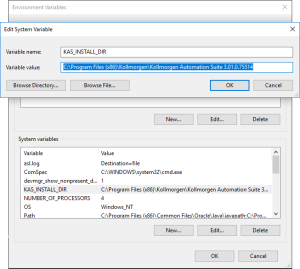

Yes, as long as one of the versions is v3.02 or later.

With the release of v3.02 multiple instances of the KAS-IDE are permitted.

That includes running one older (<v3.02) instance and any number of newer instances. This includes multiple instances of the same version. The only limitation is available RAM.

Yes, the KAS-IDE supports copying and pasting between simultaneously running instances.

- This is supported in both the same version and different version numbers.

- This includes drag and drop for supported objects (e.g., FBD blocks).

The KAS-IDE attempts to recreate what you have copied, but there are some limitations.

Example: It may not automatically associate variables with a function.

If you copy and paste only a function block from an FFLD program, the assigned variables is not copied and pasted.

If you select the entire network, the KAS-IDE automatically creates the variables for you.

|

|

| Copying a block | Copying an entire network recreates assigned variables in the Dictionary |

-

- Closing the KAS-IDE automatically clears the Clipboard.

Anything that was copied is cleared from memory.

This means you can not copy something, close the KAS-IDE, and then paste.

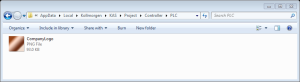

A side effect with some remaining files that were not deleted properly can interfere with your new project. To fix this issue:

- Close your current project without saving.

- Open Windows Explorer and go to C:\Documents and Settings\(user)\Local Settings\Application Data\Kollmorgen\KAS\Project, where “(user)” is the Windows' username you are currently logged in with.

- Delete all the remaining files and folders.

- You can now create your new project.

Everything in our manuals may be found in the online help.

If you need a printable document or want stand-alone manuals, the documentation is available as PDFs on KDN.

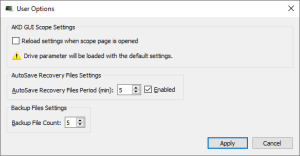

With the AutoSave function, project files are saved for recovery.

More than one file may exist due to multiple versions of the KAS-IDE being installed or used.

- When you restart the KAS-IDE you are prompted to recover a found file.

- When there is more than one file, the recovery process starts with the latest date from the newest KAS-IDE version.

- Assuming you choose to recover the file it is opened and you may resume work but the older recovery files still exist.

The next time you launch the KAS-IDE, you are prompted to recover the next oldest file. Choosing to not recover the file will delete it, and you are prompted to open the next oldest file until none are left.

Computer / Controller

This number is mainly dependent upon the application and your PC's computing power.

An average number would be 20 axes/ms.

This procedure allows you to determine if your controller is overloaded due to the PLC program or motion system load.

You can use the Softscope and the Trace Times button to display these CPU loads:

- Cycle Jitter (microseconds)

- Motion execution time (microseconds)

- PLC execution time (microseconds)

- Real Time Margin (microseconds)

To view the load:

- Open the Softscope.

- Plug four probes to any kind of data.

See Map a Variable to the Oscilloscope. - In the Control Panel, click the TraceTimes button.

See Oscilloscope Control Panel.

If you are unable to log into the controller's webpage using a valid user ID and password, the controller's file system may be corrupt.

To recover the system you will need to use the push buttons on the controller (see Boot from Recovery Image (B2 Button)) to recover the system.

Graphics need to be made portable with a project, otherwise the KAS-IDE attempts to point to the original location of the graphic files.

To make graphics portable, copy them to

C:\Users\[user folder]\AppData\Local\Kollmorgen\Project\Controller\PLC.

After this the graphics are a part of the .KAS file.

On the PCMM2G, the time is incorrect if all these conditions are TRUE:

- The controller looses power.

- Network Time Protocol (NTP) is disabled.

- There is no battery backup.

EtherCAT

An E33 occurs when the EtherCAT network fails to start when first loading a KAS project.

This typically occurs when the devices on the EtherCAT network do not exactly match the ENI file inside the KAS project.

- This can mean that devices were added, removed, or put in a different order.

- If this happens with a machine in the field that was working, it means that one or more devices are no longer being seen on the EtherCAT network because they are not powering on or an Ethernet cable came unplugged or broke.

Error Correction:

- Check the EtherCAT network wiring and devices state.

- Re-start the application.

- If you have the KAS-IDE software, you can scan the EtherCAT network to see if all the devices are found and in the correct order.

See ESI and ENI Files.

No. As with every real-time Industrial Ethernet system, one device (the master) has to be in charge of the network management and organize the Medium Access Control. With EtherCAT, Slave-to-Slave communication is supported either with:

- Topology dependent within one communication cycle ("upstream" device talks to "downstream" device).

- Topology independent within two cycles.

Since EtherCAT is so much faster than competing systems, slave-to-slave communication, using two cycles is faster.

The maximum number of node addresses is 65,535.

Typically, the number of the nodes on the network is limited by the maximum EtherCAT frame size, which is 1500 bytes.

See the Frame Size in the EtherCAT Master Settings tab for more information.

If you need to rely on SDO communication to set the parameter of an EtherCAT device, you can do this with the ECATWriteSdo FB

See Fieldbus - EtherCAT.

Being asynchronous and based on the EtherCAT mailbox, the SDO communication is not deterministic.

- The EtherCAT master uses a polling mode to ensure the SDO command is completed.

- In operational mode, this polling is performed every 50 cycles 1.

- As a consequence, you can expect the acknowledgment of your SDO command usually before less than 100ms.

- A good practice is to set the update rate for SDO communication in your PLC application each 25 cycles.

See also see "EtherCAT Motion Bus Concepts" on page 1 for more information.

The AKD2G has a limit on the number of PDO objects which can be mapped, depending on the sample rate.

| Sample Rate | Cycle Time | Max. PDOs |

|---|---|---|

| 4kHz | 250μs | 14 Rx, 14 Tx |

| 2kHz | >500μs | 30 RX, 30 Tx |

This limitation can be hit during compilation with this error:

EtherCAT: ERROR: In AKD2G_1, the total number of entries for all selected Tx PDOs is greater than the max allowed at a cycle time of 250 μs: 17 > 14

There are three possible solutions.

- Increase the Cycle Time – see EtherCAT Master Settings tab

- Deselect unused PDOs – see PDO Selection/Mapping tab

- Delete unused objects – see Delete a CoE Object

When the application runs on the KAS Simulator, the PLC execution rate is approximately 10ms.

KAS Simulator cannot execute the PLC programs faster because Windows is not able to handle timing less than 10ms.

Performance

It is generally recommended to use USB 3.0 (USB - Wikipedia) or higher standard on the PCMM2G to have a better performance.

The normal recovery image boot up is around 30 to 40 seconds.

- If the controller 7-segment display is

for a longer period of time (more than two minutes), this delay could be because the recovery image is being flashed to an incompatible USB flash drive.

- This delay may not prevent the user from following the recovery procedure.

- See Boot from Recovery Image (B2 Button) for more information.

Contact Kollmorgen Technical Support if the issue is still not resolved using a USB 3.0 or higher.

Due to excessive ASCII SDO commands or very slow Ethernet communication, the WorkBench tree may not fully populate or navigation may be unresponsive.

To recover from this situation:

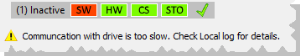

The status bar may display a warning if communication between the KAS-IDE, controller, and drive is too slow.

To begin troubleshooting, configure the Local log for WARNING level (or lower) and check for "communication too slow" messages.

The IDE-WorkBench navigation and views may become very slow or completely unresponsive if the average response time for drive communication is too long.

Communication delays between the KAS-IDE and Controller can be caused by degraded Ethernet bandwidth or high latencies.

You can use the Windows Resource Monitor (resmon.exe) and select kas_ide.exe to monitor and diagnose high latency and/or poor bandwidth.

Communication delays between the Controller and Drive can occur while an application is running on the controller.

Degraded drive communication can be caused by excessive ASCII SDO commands from the application code.

- Check your application code for calls to DriveParamRead/Write(...), DriveParamStrRead(...), or ECATRead/WriteSdo(...), and minimize the frequency of these calls.

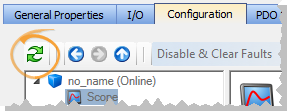

- Use Online Configuration Mode with KAS-IDEWorkBench to avoid ASCII SDO channel competition between your application and KAS-IDEWorkBench

There are times when trying to connect to multiple drives simultaneously with WorkBench is problematic, particularly on slower networks.

Resolution

- Close all of the open windows in the IDE workspace, leaving only one WorkBench window open.

- Connect the KAS-IDE and run the project or use Online Configuration mode.

These actions reduce the network and KAS-IDE loads. This allows the embedded WorkBench to establish communication and access the views.

To access multiple drives at the same time:

- Open one WorkBench window

- Wait for communication and initialization to complete successfully

- Open each additional WorkBench window one at a time.

Allow enough time for each to successfully complete initialization.

Programming

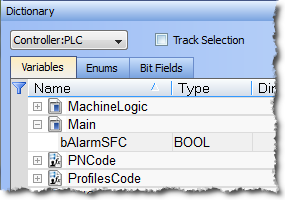

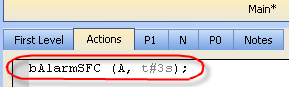

When you want to check the maximum time execution for an SFC step, you have to program this action based on the SFC alarm capability.

To show this status:

- In the Dictionary, declare a Boolean PLC variable linked to the related SFC program.

- Add the instruction in the Actions tab related to the SFC step, with first parameter set to A (for Alarm).

The syntax is explained in Actions in an SFC Step.

More details on the timeout on an SFC step are in Timeout on an SFC Step.

If you open a project containing a link on a library which is no longer available, a warning is displayed. To fix this issue, refer to (➜ # 1, What happens when a library no longer exists?)

The Fast Input allows an application to get information about the occurrence of an external event at a higher resolution than the cycle time.

For more details, see Fast Inputs with Pipe Network Motion.

There are two kinds of feedback:

Primary Feedback

- With a S300 drive you can use a resolver for primary feedback.

- If a secondary feedback is required with your S300 drive, you can use a BiSS feedback device.

- If you use the same setup with an S300 drive, the S300's EXTPOS parameter has to be set to -11.

IMPORTANT: do not omit the negative sign! - To access secondary feedback, use a SAMPLER Pipe Network block.

- If you use the same setup with an S300 drive, the S300's EXTPOS parameter has to be set to -11.

- Use the MLSmpConPNAxis, MLSmpConPLCAxis, or MLSmpConECAT functions to configure the block.

Current drives that support torque feed-forward arethe S300 and AKD drives.

To use torque feed-forward, you have to rely on a CONVERTER Pipe Network block.

Use the MLCNVConnectEx function to configure the block.

The arguments must be:

- The Pipe Network block ID being configured.

- The ID of the axis to which the torque feed-forward is applied.

- The constant EC_ADDITIVE_TORQUE_VALUE.

- An ignored integer value (usually set to zero).

For more information, see:

If I measure a number (e.g., 500) as an input at the Convertor block which is connected with the PDO object (Additive Torque Value 0x60B2), how many Amps are fed in the current loop at the AKD?

Current loop feed-forward value = Rated current x IL.KBUSFF x input at converter block / 1000

Example: With an AKD where:

| Rated current | 3A |

| IL.KBUSFF | 1.0 |

| Additive Torque (PDO object) | 500 units |

Then

IL.FF = 3 x 1.0 x 500 / 1000 IL.FF = 1.5A

There is no limitation with the cams, the number of cams, the number of cam points, etc.

The limitation is only given by the processing power of your PC.

See also see "Pipe Block Descriptions" on page 1 for more information.

Yes, I/O points represent the state of real world values.

See Use Motion Function Block for Pipe Network for this information.

The system needs to know where to place the copied blocks.

Press Ctrl-V then use the mouse to point to where you want the copied blocks to be pasted.

There are network and mechanical delays in systems that make capturing a correct pipe position difficult.

To remove the delays, use a sampler block to capture the actual position of an axis.

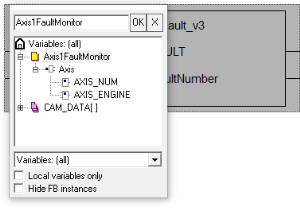

This image shows how this works:

- This sampler block is configured to capture the actual position of axis 1.

- The conversion and axis blocks are only needed to terminate the pipe.

- MLTrigWriteDelay may still be needed to compensate for sensor delay.

- If you need to calculate the master pipe value corresponding to the captured axis position, add the difference between the axis command position and the master pipe value.

If a hardware limit flag is being triggered at the program startup by a Pipe Network axis, MLAxisReAlign may need to be called immediately before motion occurs.

In this case, the distance to travel should be at least as long as the maximum distance the hardware limit flag can remain active.

Setup

The fieldbus serially links all the drives to the industrial PC.

See the figures in (➜ # 1, Different Implementations) for more information.

-

When the KAS-IDE is used to deploy an automation system on a master drive (also known as programmable drive), the fieldbus serially links all the drives to the master drive.

KAS can communicate with outside world through Ethernet, CANopen, DeviceNet.

See (➜ # 1, Communication and Fieldbus) for more information.

Description

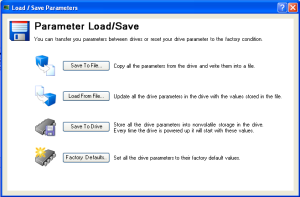

This issue occurs with these actions:

- Connect to the controller and download your application.

- In the Project Explorer, open the EtherCAT properties.

- Click theOnline Configuration Mode.

- In the Project Explorer, right-click the AKD_1 and select Load/Save Parameter….

- Select the Factory Defaults… command to reset the drive to its default parameters.

Reason

If you set the drive to its default parameters, then all the AKD parameters are restored and the unique ID (FBUS.PARAM03) used to identify the drive is lost.

Solution

You have to perform a new scan operation after setting the parameters to its default values.

-

You can also clear the Write a unique ID option in the XML configuration tab.

See the click here... for more information.

If you encounter any security issues during execution of Kollmorgen Automation Suite, contact your IT department to set your proxy properly.

Firewall

You may have to define your firewall settings to allow accessing the IP addresses used by KAS (e.g., IP address of the target system or localhost IP address for the KAS Runtime Simulator: 127.0.0.1).

Port Numbers

Port numbers have to be set properly in your firewall settings to avoid any trouble during communication, such as when downloading the application to the target or plugging a probe to the Softscope.

Kollmorgen strongly recommends opening port numbers over 1024, as well as the range 502 to 520.